- Joined

- Dec 20, 2021

- Messages

- 894

If the engine hoist won't do it, it gets blocked up and put on a pallet jack. However for 'small' things, the engine hoist is faster. For the record, I have dented sheet metal with the tractor. And it hurts even more when it's brand new sheet metal, lol.When an engine lift won't cut it, and every rental yard in the PNW is out of forklifts, you can rent a reach lift... Only cost me $950 for 30 minutes use! Yes, the dent in the door flashing was from the boom. This was last week. And a shop without a lathe is worse than a shop without a drill press... or maybe a bench grinder. Or 10mm sockets.

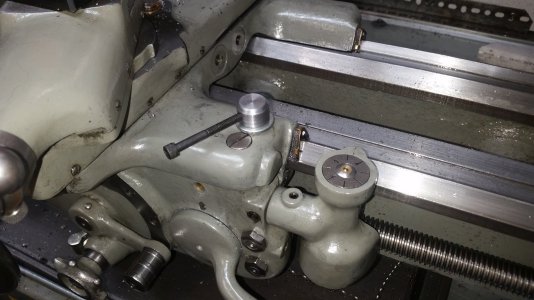

Yep, not looking foreword to the shop without the lathe. I'm already running into things I should do on the lathe, but can't! Right now I'm imagining a tooling block in the CNC mill vise and G code to 'turn' parts in the mill... ...seen a few youtube videos, and this might be the chance to try that out.

That reminds me, the 1/4" drive 10mm in my set is still misplaced...