- Joined

- Oct 9, 2014

- Messages

- 465

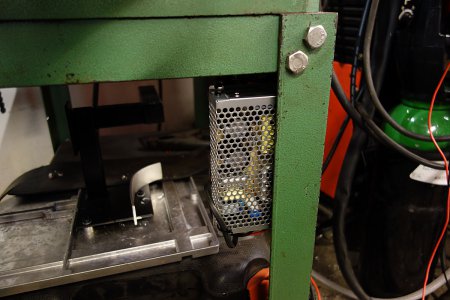

I use this drill press a lot for drilling, and for milling when the vintage bench mill is too small. I've had a power feed on it but the solution was too weak. It uses a windscreen wiper motor and it went south without much use.

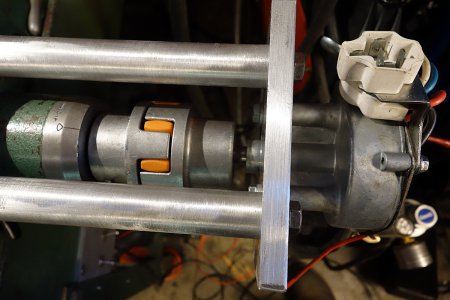

So I'm now changing to a much larger wiper motor and also put a flexible joint in between. The support fixture between the table and motor remains to fabricate. It will be two 1, 25 " studs from the table to a 1/2 inch plate on the motor gear house.

So I'm now changing to a much larger wiper motor and also put a flexible joint in between. The support fixture between the table and motor remains to fabricate. It will be two 1, 25 " studs from the table to a 1/2 inch plate on the motor gear house.