- Joined

- Feb 23, 2016

- Messages

- 424

Just a quick update. Still no news of the mill that I ordered in Nov. Have called PM last Monday: they have received the container from Taiwan, and are going through the back orders in the order they were received. The guy on the phone told me my order will fit into this batch of mills, so I am hopeful to have my toy soon.

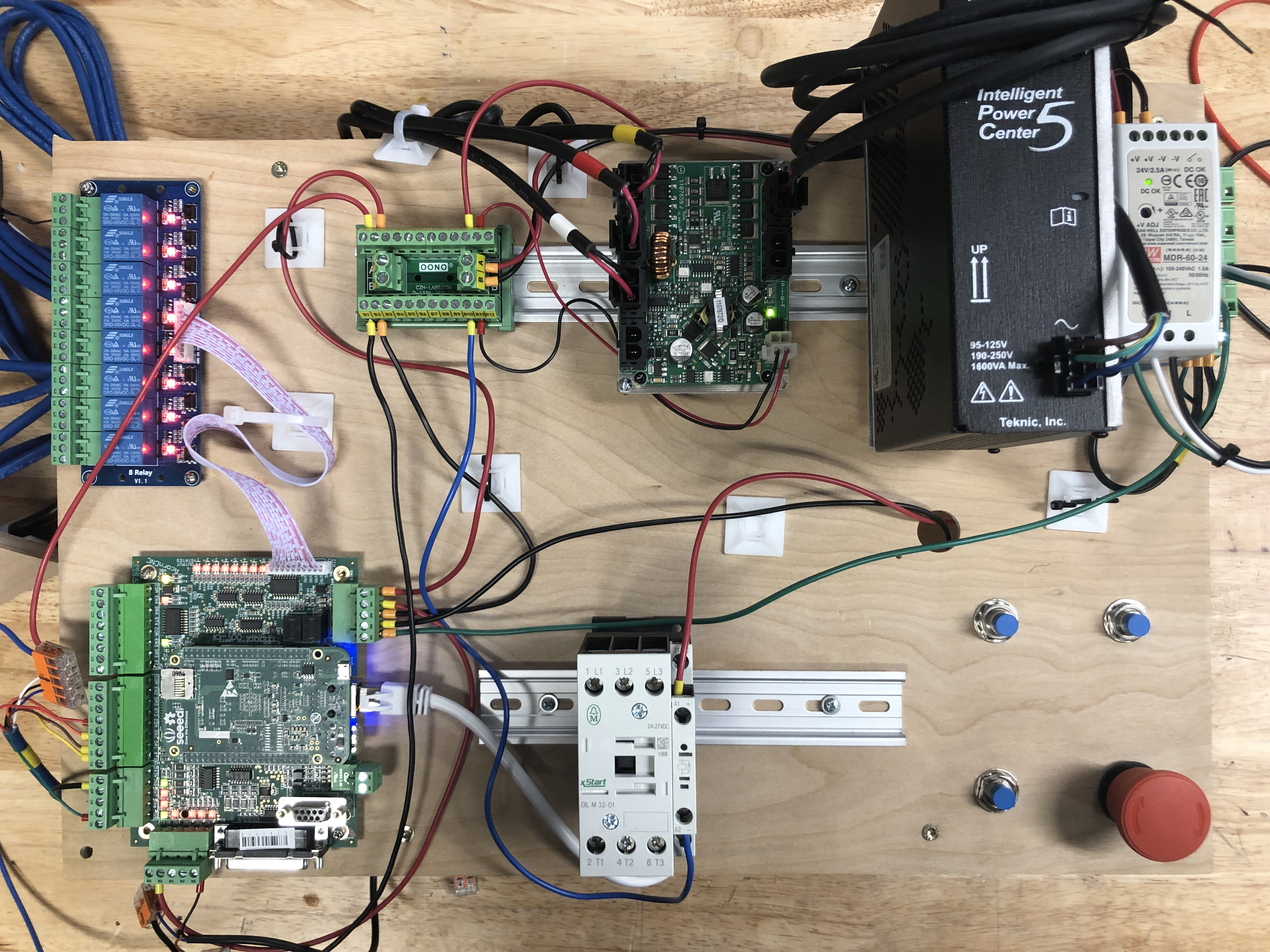

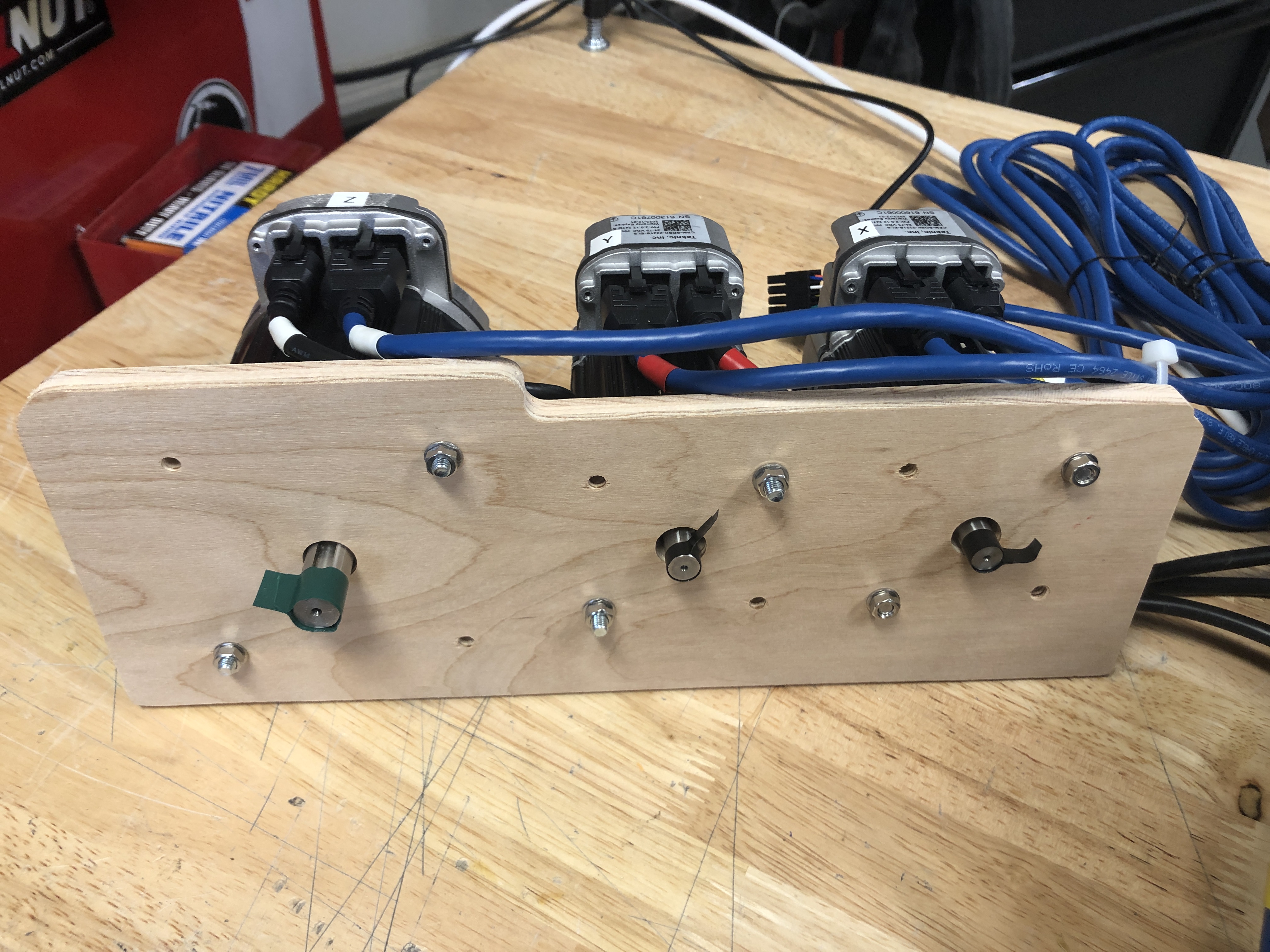

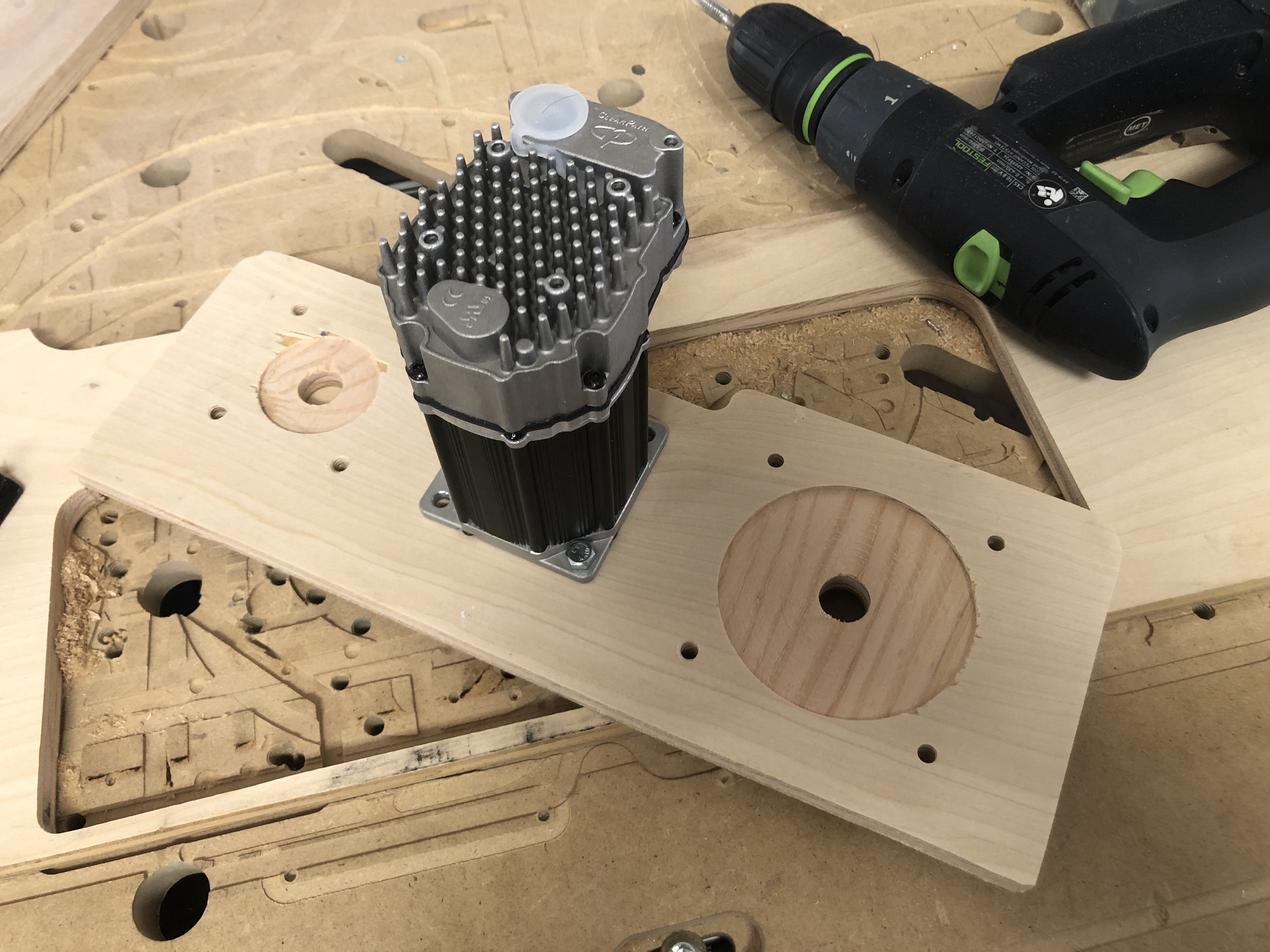

In the meantime, have received the complete ClearPath package from Teknic. So today I set out to wire it up on a piece a plywood; added some legs that I cut from an old closet dowel, so cabling can be tucked under. Also attached the motors to a piece of plywood so they don't flop around. After configuring the steps in the Teknic configurator, I managed to wire up one motor following the Acorn schematic. Then I added the contactor, and after I figured that out, added one proximity sensor, that can be tripped and stops the corresponding motor. Very pleased how everything worked out.

I decided I will use 6-pin aviation connectors for the gland plate of the enclosure, instead of Molex.

Still to do:

1. Get NC (normally closed) proximity sensors, instead of the current NO sensors. Small point, but worth it; in case the connection is dropped, you find out before you crash.

2. Need to find sensors that have 4 pin aviation style connectors from the body of the sensor to the enclosure. Will wait until the mill arrives to see the actual physical limitations, and see if I need 90-degree plugs or straight.

In the meantime, have received the complete ClearPath package from Teknic. So today I set out to wire it up on a piece a plywood; added some legs that I cut from an old closet dowel, so cabling can be tucked under. Also attached the motors to a piece of plywood so they don't flop around. After configuring the steps in the Teknic configurator, I managed to wire up one motor following the Acorn schematic. Then I added the contactor, and after I figured that out, added one proximity sensor, that can be tripped and stops the corresponding motor. Very pleased how everything worked out.

I decided I will use 6-pin aviation connectors for the gland plate of the enclosure, instead of Molex.

Still to do:

1. Get NC (normally closed) proximity sensors, instead of the current NO sensors. Small point, but worth it; in case the connection is dropped, you find out before you crash.

2. Need to find sensors that have 4 pin aviation style connectors from the body of the sensor to the enclosure. Will wait until the mill arrives to see the actual physical limitations, and see if I need 90-degree plugs or straight.

Last edited: