Octopi is based on a Raspberry Pi computer card. It allows you to remotely send files to the printer, see where the printer is, ie, which layer is it at, and to stream video remotely to your computer. You can also abort the job from your PC. It's rather nice in many ways. The down side, these days, is it is difficult to buy Raspberry Pi's these days due to the chip shortages.

I think you can use an Orange Pi, if you can figure out how to do set it up.

Octopi itself is a downloadable image that fully includes setting up the Raspberry Pi itself. Just download the image, burn a microSD card, insert in the RPi and turn it on. Optionally you can plug in a cheap webcam. The Prusa came with a USB cable. Plug one end into the Prusa, and the other into Octopi. You open up a window in your browser that points to Octopi, typically octopi.local, and you have a full web interface to your printer. You need an RPi3 or higher to run it. I am using an RPi3B and it works fine. It really is quite nice. If you have a spare suitable RPi, I highly recommend it. I used it from the get go, don't like dealing with SD cards.

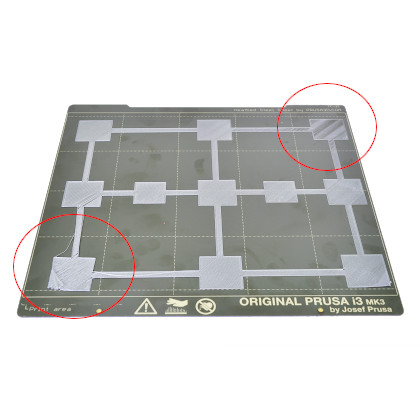

Octopi has a bunch of software plug ins that can add capability. One of them was a print bed visualizer for flatness.