I am looking at the holders on the Aloris site as a starting point to figure out which one I would need for my 12x36 Craftsman with the commercial saddle and cross feed. Do I need AXA, BXA or CXA? I am not at home so I can't measure it.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

QCTP holder

- Thread starter DiscoDan

- Start date

- Joined

- Dec 21, 2013

- Messages

- 798

BXA would be my choice................

L

Lordbeezer

Forum Guest

Register Today

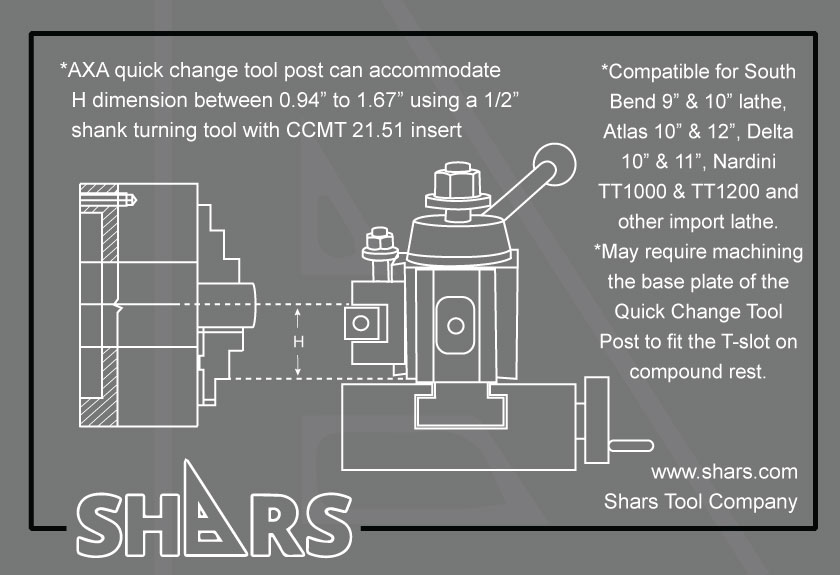

Think after you measure you might see a axa might fit better.

Dabbler, do you have the commercial cross slide or the non-commercial? It looks like the non-commercial one is taller than my commercial. I have the measurements so I guess I will find out when I get home.

- Joined

- Feb 13, 2014

- Messages

- 369

BXA would be my choice................

Used BXA on mine against much sage advice on this forum. Have been very pleased. Bought used w/5 tool holders for less than 75$. Happy happy happy

Dave