- Joined

- Oct 31, 2016

- Messages

- 2,645

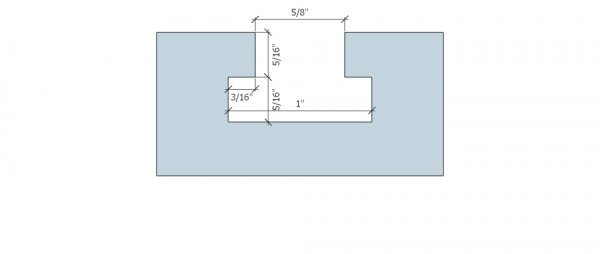

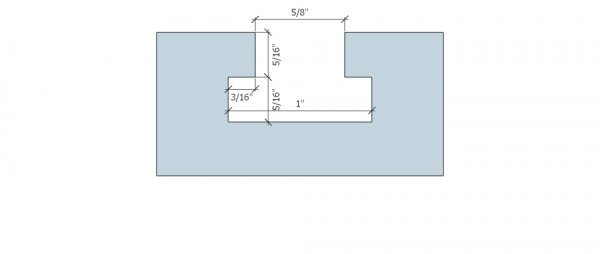

I will not even attempt to widen the slot. Doing so accurately is probably beyond my skill level and I would then have a non-standard/modified compound. Who knows what problems that might create down the road. I probably misspoke using the term "T nut." Here is a sketch of the compound slot.

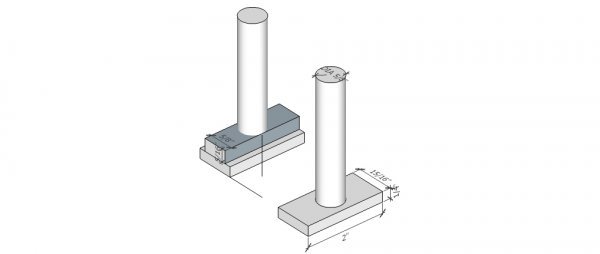

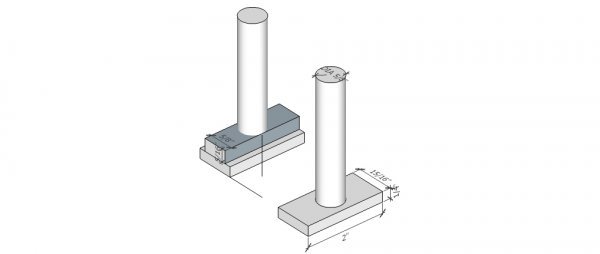

And here is what I am thinking of making to replace the carriage bolt. I left off the threads. Too hard to draw quickly.

My T nut would be a 1/4 x 15/16 x 2" with a 5/8 threaded post. The post will either be welded in place or screwed into a threaded hole in the base plat.

And here is what I am thinking of making to replace the carriage bolt. I left off the threads. Too hard to draw quickly.

My T nut would be a 1/4 x 15/16 x 2" with a 5/8 threaded post. The post will either be welded in place or screwed into a threaded hole in the base plat.