- Joined

- Mar 18, 2023

- Messages

- 19

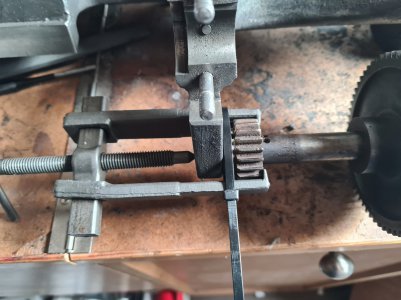

It's frustrating, I am trying to remove the back gear but can't because a tapered pin is stuck in place. I'm drilling it out now, but it's a job I find difficult to do wrong handed.Sorry to hear about your shoulder . Get well soon ! Lathe is looking good .

Mark .

I have a pillar drill, but it's to heavy for me to set up.