- Joined

- Dec 18, 2019

- Messages

- 6,464

Been having a problem with a back flow valve for my irrigation system. The back flow valve weeps, and recently has gotten a lot worse. Took it apart mostly to see what the insides looked like. Cleaned the plastic piston and found a crack in the face. This piston takes 45 psi. If I hadn't found the crack, I would have just replaced the o-ring and reassembled it. Think I will make a replacement piston.

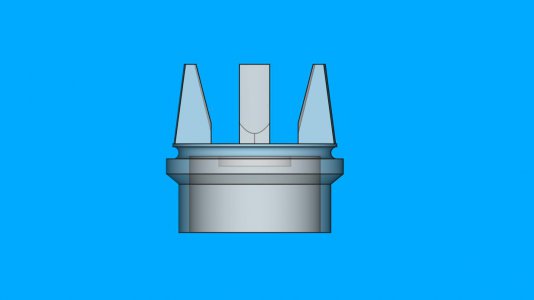

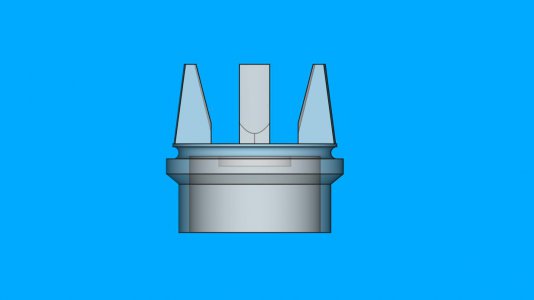

Removed the o-ring, is seems to be 3/32" and 1.25" ID, which makes it a 124. With the use of calipers and a micrometer, measured up the piston and made a CAD model. I made the ears wider, as they are just locating a spring. The cross in the bottom was replaced by a raised disc. There is also a second spring in the valve which seats against the cross. The bottom of the valve has some metal spring guides which touch the region between the end of the cross and the ID. Here is the CAD rendering so far.

I need to work on the angles of the ears, as they are not quite correct. I think this first attempt will be in aluminum even though this isn't the best material for longevity as this will be immersed in water with steel springs on both sides. I have some 304, but I had some problems with machining it.

Not quite sure how to machine this piece just yet. Making the raised button inside the bore seems like that would be interesting. Thought I would machine the ears last and hold the workpiece in some soft jaws for the mill work. Not sure about the o-ring groove, do they make 3/64" radius grooving tools?

Removed the o-ring, is seems to be 3/32" and 1.25" ID, which makes it a 124. With the use of calipers and a micrometer, measured up the piston and made a CAD model. I made the ears wider, as they are just locating a spring. The cross in the bottom was replaced by a raised disc. There is also a second spring in the valve which seats against the cross. The bottom of the valve has some metal spring guides which touch the region between the end of the cross and the ID. Here is the CAD rendering so far.

I need to work on the angles of the ears, as they are not quite correct. I think this first attempt will be in aluminum even though this isn't the best material for longevity as this will be immersed in water with steel springs on both sides. I have some 304, but I had some problems with machining it.

Not quite sure how to machine this piece just yet. Making the raised button inside the bore seems like that would be interesting. Thought I would machine the ears last and hold the workpiece in some soft jaws for the mill work. Not sure about the o-ring groove, do they make 3/64" radius grooving tools?