- Joined

- Oct 10, 2018

- Messages

- 543

As @C-Bag says, we try hard not to offend new folks (or anyone!) on this forum so forgive me if I'm suggesting something you already know.Yes I've loosened all the locks and pulled the motor all the way forward as far as it will go after some serious muscle I got the original belts on but I could not even pry them off I had to loosen the motor to Pivot it forward to be able to even pry the belts off ...

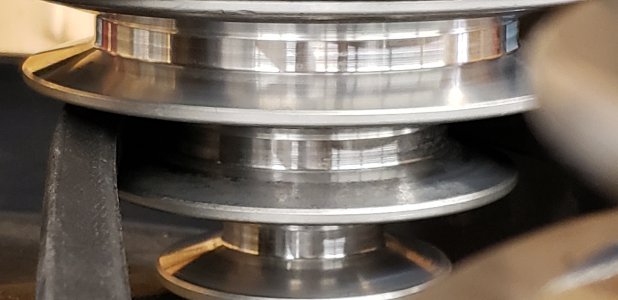

You don't want to "pry belts off". They should 'roll' off. By that, I mean you start by lifting the belt on one edge and rolling/guiding it up onto the lip of pulley. Continue rotating the pulley & belt and lifting the belt so it climbs up and over the lip. It will get quite tight but eventually you will get to a point where it 'pops' loose. Be careful of your fingers!!

I usually take belts off towards the larger pulley. Putting a belt back on is the reverse of taking it off but I usually then use the smaller pulley. Again, mind your fingers!!

Could not find a good video showing this process. You can kinda/sorta see what I'm talking about at the 50 second mark in the following video:

Craig