-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rockwell mill lubrication upgrade

- Thread starter Weldingrod1

- Start date

-

- Tags

- lubrication rockwell

- Joined

- Oct 14, 2013

- Messages

- 997

Ball Oilers out... broke down and.pulled the drive and quill. Added three more lube points!

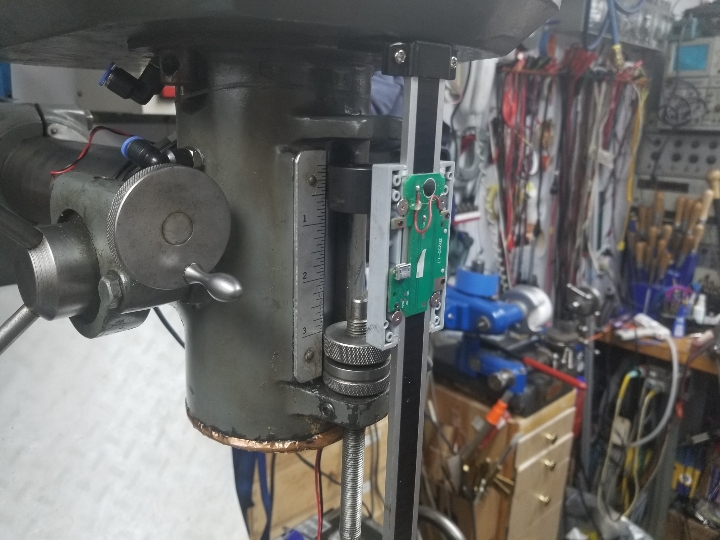

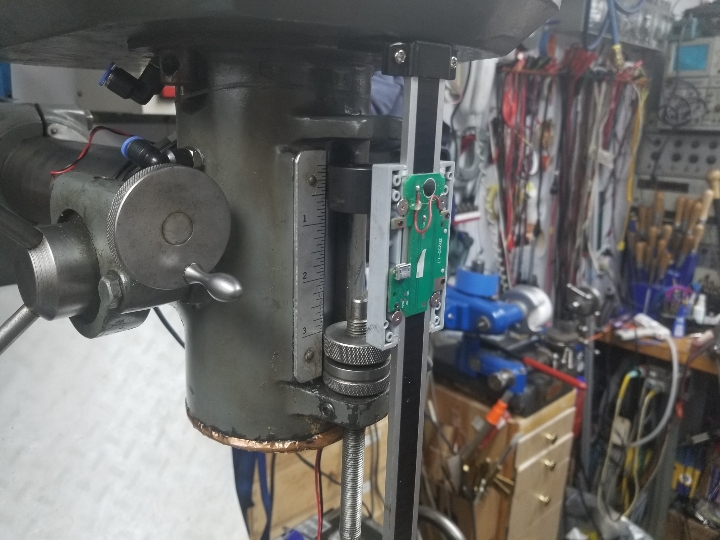

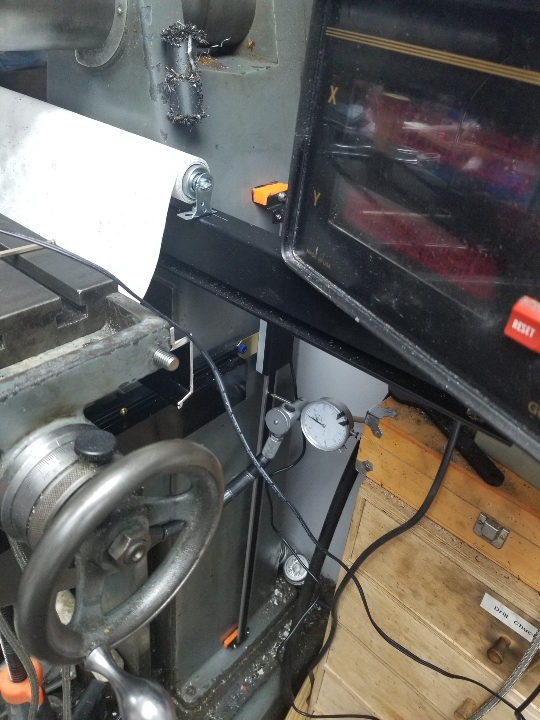

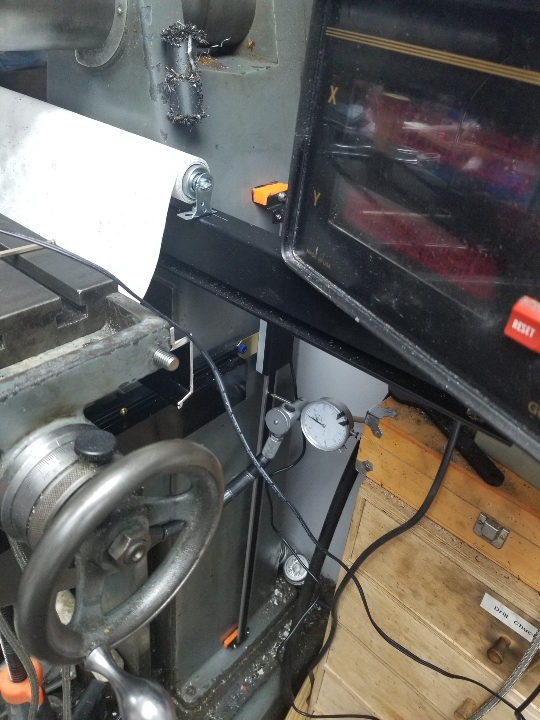

Got the initial mounting on the quill DRO.

I tapped one 5/16", but that made so many chips I decided I had to pull the spindle.

I just used a punch to drive out the other one. They don't line up, of course!

Sent from my SM-G892A using Tapatalk

Got the initial mounting on the quill DRO.

I tapped one 5/16", but that made so many chips I decided I had to pull the spindle.

I just used a punch to drive out the other one. They don't line up, of course!

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

Oil cups would be good on the side ones, but you need felt to keep it from all running out when the quill is down.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

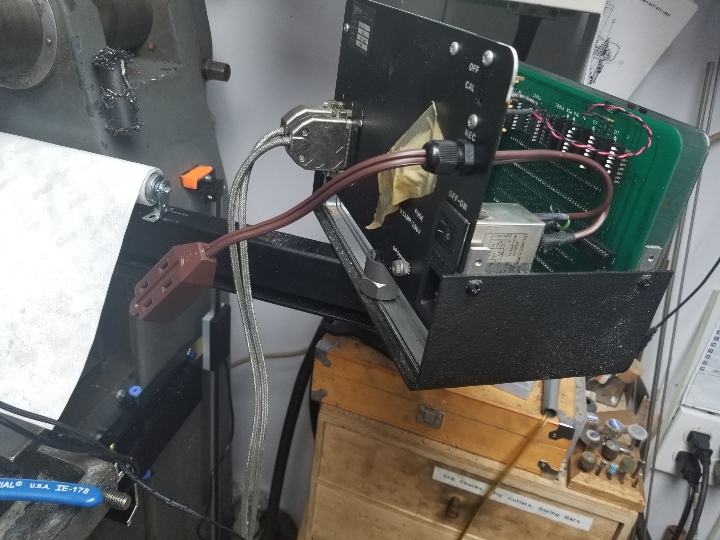

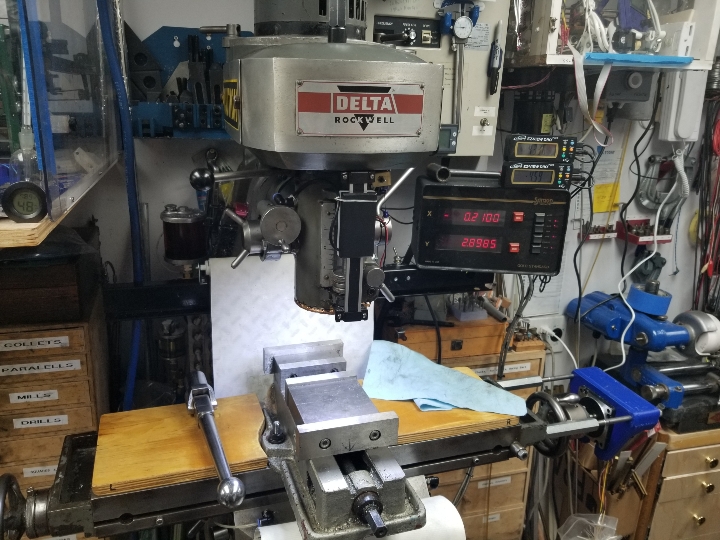

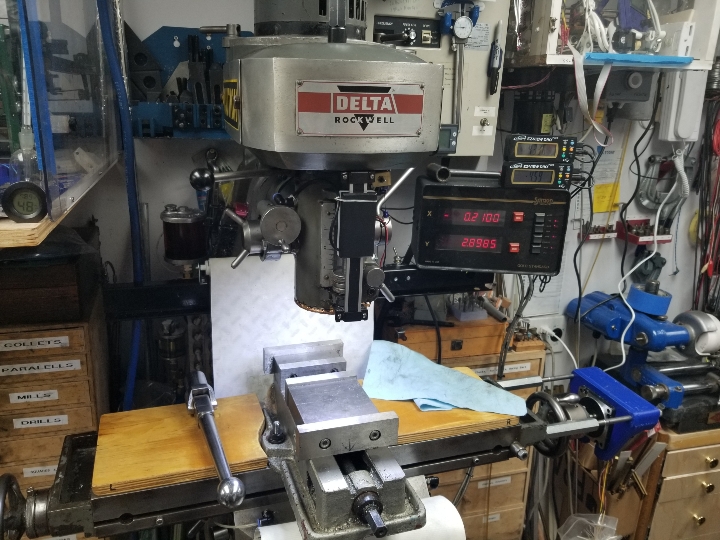

Z axis DRO added. I used a flexure between the knee and the read head.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

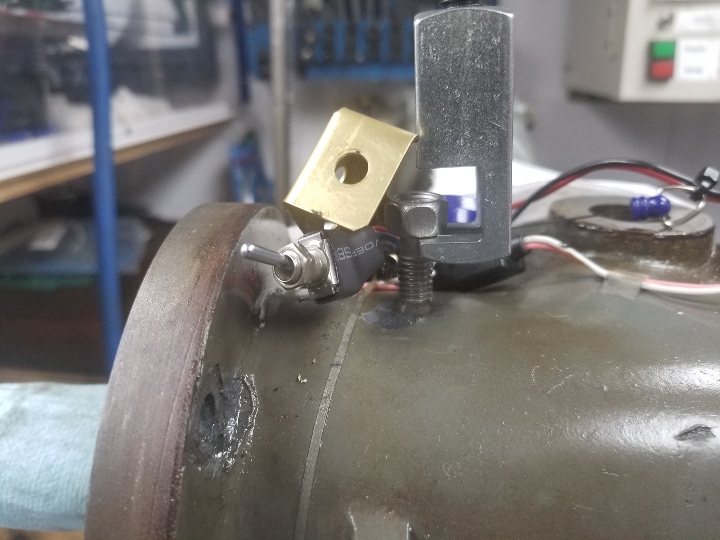

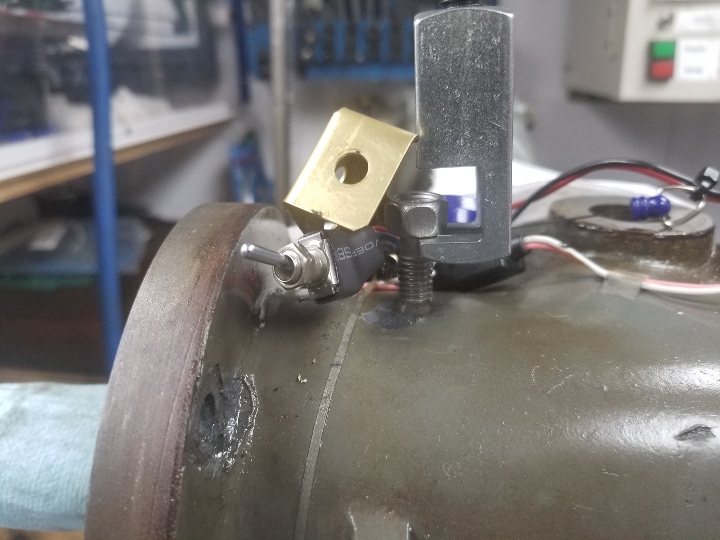

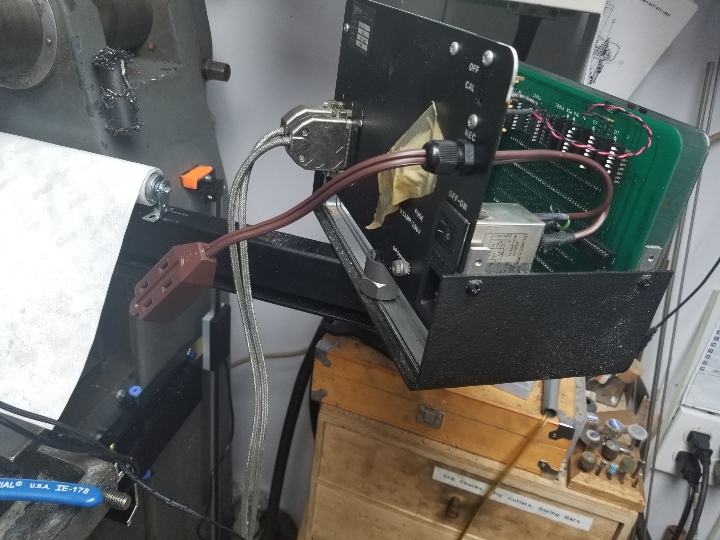

Adding power for the new axies and the ring light. One switch to rule them all!

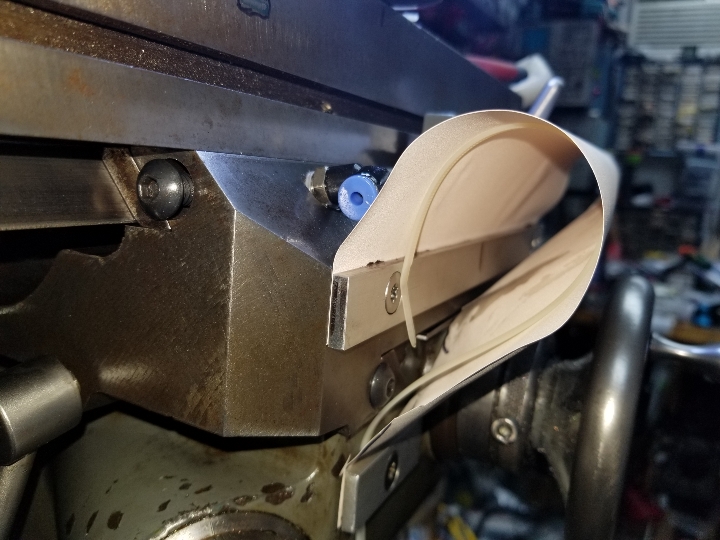

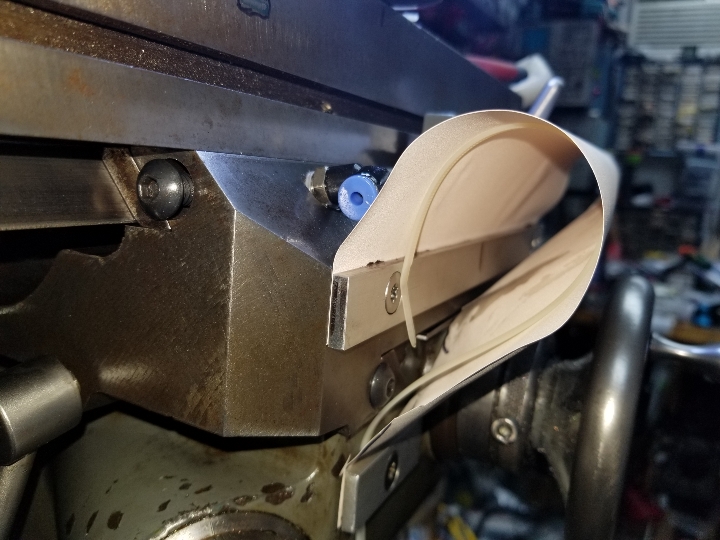

Noodling on the front cover... zip ties for springs?

And, a "aw, #%^&" note; the lock hits a lube port.

Sent from my SM-G892A using Tapatalk

Noodling on the front cover... zip ties for springs?

And, a "aw, #%^&" note; the lock hits a lube port.

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

As I was telling Doc Nickle, I also bent that screw severely a few years back. I really just need to make a longer one that clears ;-)

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

Argh. My fleabay pump brick needs to be cleaned out so it pumps right. Hopefully I wont have to re-sesl the whole thing.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

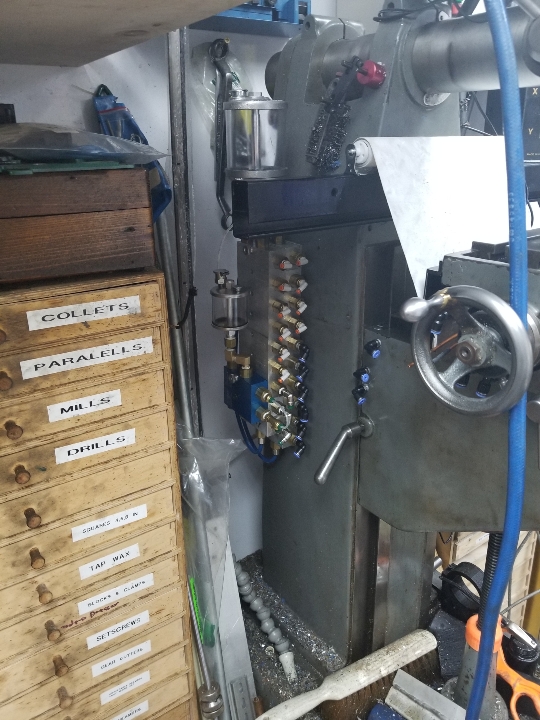

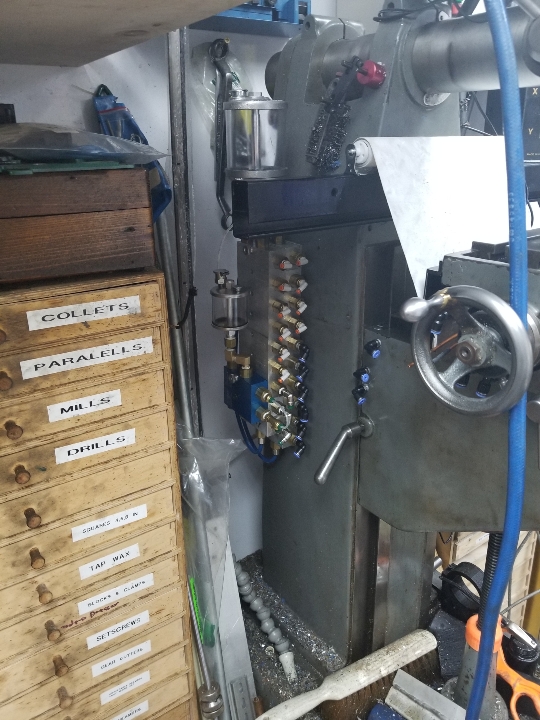

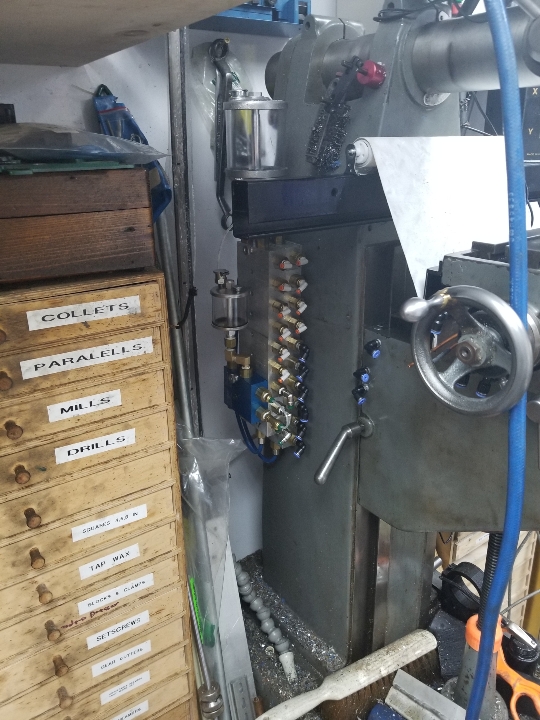

Cleaned out and got all 20 pumps cycling. Whee. I love the parts washer...

Mounted them, next.up is a spaghetti farm!

Sent from my SM-G892A using Tapatalk

Mounted them, next.up is a spaghetti farm!

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 14, 2013

- Messages

- 997

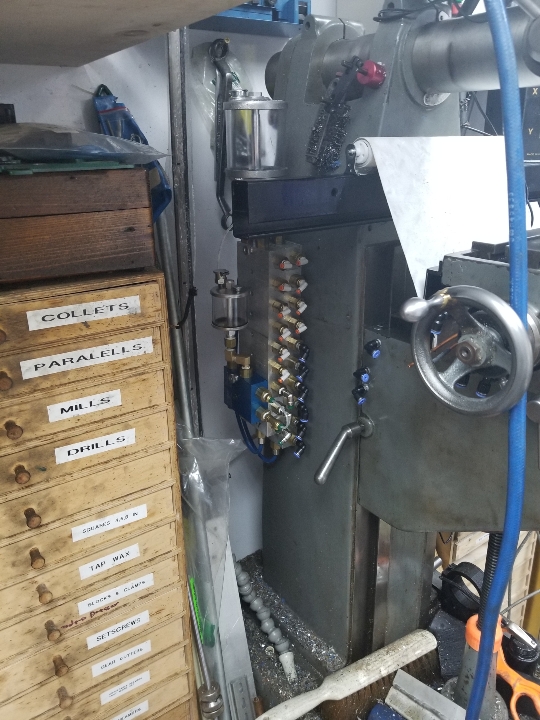

I've got oil drooling out everywhere now

Cables and hoses, rendered, Gibs adjusted, vise lined up, head trammed!

The only outstanding thing is upgrading the power feed with some actual switches...

Sent from my SM-G892A using Tapatalk

Cables and hoses, rendered, Gibs adjusted, vise lined up, head trammed!

The only outstanding thing is upgrading the power feed with some actual switches...

Sent from my SM-G892A using Tapatalk