-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

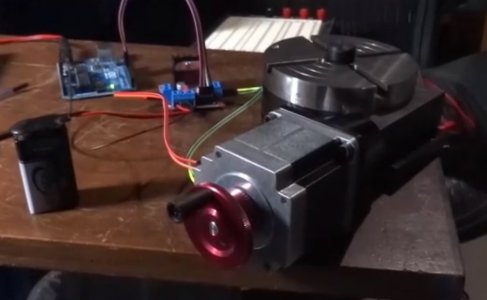

Rotary table/indexer controller.

- Thread starter EricB

- Start date

- Joined

- Feb 15, 2020

- Messages

- 375

- Joined

- Feb 25, 2021

- Messages

- 3,130

Just started working on this: https://www.hobby-machinist.com/threads/rotary-table-automation.102461/page-3#post-991727

In addition to basic rotary control I'd like to add an encoder to track the x-axis leadscrew for spiral cutting, etc.

In addition to basic rotary control I'd like to add an encoder to track the x-axis leadscrew for spiral cutting, etc.

- Joined

- Apr 30, 2015

- Messages

- 11,316

I built an electronic dividing head using Arduino code online- Here's the link:

The code seems to be very solid

-Mark

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

The code seems to be very solid

-Mark

Arduino Rotary Table for Dummies

Ive had a few people tell me that they like the project (http://www.homemodelenginemachinist.com/showthread.php?t=25783) but dont feel comfortable with the electronics. Ive been playing around to simplify it down to where I feel anyone who wants to could comfortably build the controller. With...

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Last edited:

- Joined

- Feb 15, 2020

- Messages

- 375

After some experimenting, it seems to me that the thing to do is leave the motor disabled until it's time for a move. Then when a move is needed, pull the enable lines high, drive to the new position, then drop the enables low.

The pro is the driver doesn't cook itself just holding the motor position. Mine got up to egg frying temp in just a few minutes.

The con is very little holding torque.

Thoughts?

Eric

The pro is the driver doesn't cook itself just holding the motor position. Mine got up to egg frying temp in just a few minutes.

The con is very little holding torque.

Thoughts?

Eric

- Joined

- Dec 18, 2019

- Messages

- 6,447

In normal operation for the driver is the hold current the same as the stepping current? Can your driver reduce it's hold current? I have an ELS using a stepper, it doesn't get particularly hot. Mine is 4 Nm, NEMA 24. Of course my lathe is the heatsink. I've left the motor on, but not stepping and it seems ok, it's not hot. I'm using a closed loop stepper motor driver that has various current settings. A CL57T, I think.After some experimenting, it seems to me that the thing to do is leave the motor disabled until it's time for a move. Then when a move is needed, pull the enable lines high, drive to the new position, then drop the enables low.

The pro is the driver doesn't cook itself just holding the motor position. Mine got up to egg frying temp in just a few minutes.

The con is very little holding torque.

Thoughts?

Eric

If you are using the stepper just to position and stop, then you could use the locks on the RT. Can't do that if the RT is rotating!

- Joined

- Feb 25, 2021

- Messages

- 3,130

I'm planning on using the rotary table locks on mine if it needs to hold in place. I'm using a clearpath servo, so the microcontroller can monitor torque (via an A/D converter) to warn if the table is locked when trying to turn.After some experimenting, it seems to me that the thing to do is leave the motor disabled until it's time for a move. Then when a move is needed, pull the enable lines high, drive to the new position, then drop the enables low.

The pro is the driver doesn't cook itself just holding the motor position. Mine got up to egg frying temp in just a few minutes.

The con is very little holding torque.

Thoughts?

Eric

I believe simple stepper drivers are essential a current source, varying the voltage to get a steady current. I wonder if you could hack the driver to adjust the current settings dynamically by controlling the DIP switches from your microcontroller, so you could drop to something like 75% current for holding.

Last edited:

- Joined

- Feb 15, 2020

- Messages

- 375

The data sheets tell that current can be controlled buy selecting the proper "sense" resistor, but don't elaborate further. I guess you need an EE degree for that. Holding current as tested is 1.4 amps per coil. The driver is rated 3 amps max per channel. I guess it needs a bigger heat sink.I'm planning on using the rotary table locks on mine if it needs to hold in place. I'm using a clearpath servo, so the microcontroller can monitor torque (via an A/D converter) to warn if the table is locked when trying to turn.

I believe simple stepper drivers are essential a current source, varying the voltage to get a steady current. I wonder if you could hack the driver to adjust the current settings dynamically by controlling the DIP switches from your microcontroller, so you could drop to something like 75% current for holding.

- Joined

- Feb 15, 2020

- Messages

- 375

I would need to check the current while stepping.In normal operation for the driver is the hold current the same as the stepping current? Can your driver reduce it's hold current? I have an ELS using a stepper, it doesn't get particularly hot. Mine is 4 Nm, NEMA 24. Of course my lathe is the heatsink. I've left the motor on, but not stepping and it seems ok, it's not hot. I'm using a closed loop stepper motor driver that has various current settings. A CL57T, I think.

If you are using the stepper just to position and stop, then you could use the locks on the RT. Can't do that if the RT is rotating!

In it's present configuration I can't adjust output current. I just checked and the board has the current setting pins tied to ground, so it's set for max output current. Time to get the soldering iron out.