That's a possibility, Bob. (Nice trailer)

I think I have a plan for it. It will require a lot of pieces, and I'm not sure how far apart the ribs will need to be.

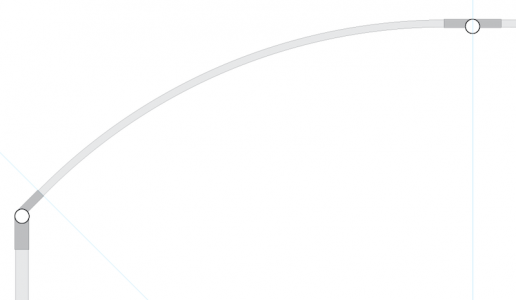

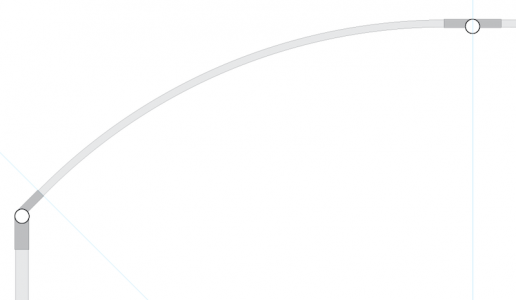

Here is the general structure and contour. 45º of a 10' diameter for the ribs. Ribs are 1/2" rigid conduit.

The peak and sides are 1.5" rigid conduit which is a good collar size for chain link fence top rail which can be the sides, roof peak rod and legs.

Each half of the arch is about 4.5 feet and the whole thing spans about 6 feet. It'll need to be at least 16 feet long.

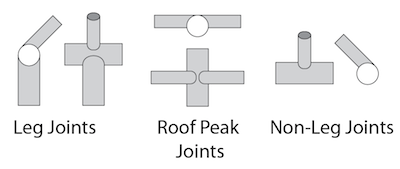

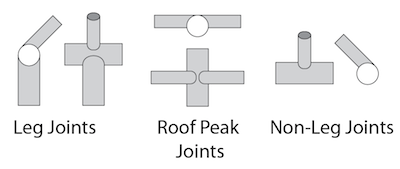

Here are the tinker toy corners made from 1.5" rigid conduit and 7/8" .065 wall DOM A513 Type 5 steel tube.

The joints will just slide on the top rail tubes. I can experiment by making a few and trying different spacing.

I'm hoping I can get by with them on 24" centers which would require about 8 per side,

but I have a feeling (based on nothing) that's too much spacing, though I've seen on in Northern Tool catalog that looks like the ribs are on 24" centers.