-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SB Model A wiring quandary.

- Thread starter pntr

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,305

- Joined

- Apr 30, 2015

- Messages

- 11,309

OK. Motor reversing class 101. You need 4 wires from motor to switch (plus ground makes 5) for 120 volts configuration.

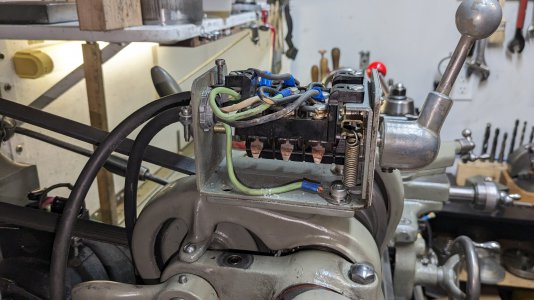

I believe you have a "3-phase" type reversing switch- it will work fine if connected properly.

Most motors have an instruction like "swap wires red and black to reverse" or similar. We need that.

If there is no data plate for the motor we might need to test it with a meter. What motor info do you have?

-Mark

I believe you have a "3-phase" type reversing switch- it will work fine if connected properly.

Most motors have an instruction like "swap wires red and black to reverse" or similar. We need that.

If there is no data plate for the motor we might need to test it with a meter. What motor info do you have?

-Mark

Last edited:

This is the only info I have on the motor. It's an ancient thing. The lathe was sitting for at least 40 years, indoors and only had dust on it. I suspect it was set up for 220 originally but it got switched over to 110 in the 70s. I don't have access to 220 where I live in an apartment and the lathe is in the garage I have beneath my place. The serial number is 5KC43MG686E. I wasn't able to find much info on it that made any sense to me.

I may have to break down and get a different motor with some actual paperwork I suspect. I probably won't be using reverse all that much insomuch as the chuck is on a threaded spindle and I don't want it to unscrew itself. I'm not doing any kind of heavy torque machining so it's not that much of a concern but I'd really like to try cutting threads the way I saw a YouTuber named Joe Pi do them which is in reverse with the cutter upside down.

- Joined

- Nov 25, 2015

- Messages

- 8,305

many times the old motors would have a diagram on the back of that spec plate. see if yours does. a few of mine did.

- Joined

- Feb 26, 2021

- Messages

- 470

Good call. There are two plates on the back of that motor. I'd remove the plate by the wiring, opposite side of motor from that ID plate.many times the old motors would have a diagram on the back of that spec plate. see if yours does. a few of mine did.

- Joined

- Apr 30, 2015

- Messages

- 11,309

Is this a capacitor start motor? Does it have the familiar bulge cover on the side?

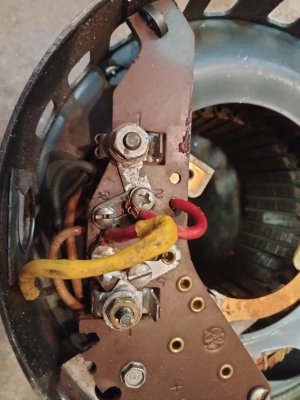

It's a 1/2 HP so it will run fine on a standard 120 volt circuit. Power connects to the two threaded studs.

I believe those two red wires are the start wires, swapping those should reverse it. We should test that

before connecting the drum switch.

Reverse is useful for cutting metric threads- unscrewing the chuck is not a concern during that process

It's a 1/2 HP so it will run fine on a standard 120 volt circuit. Power connects to the two threaded studs.

I believe those two red wires are the start wires, swapping those should reverse it. We should test that

before connecting the drum switch.

Reverse is useful for cutting metric threads- unscrewing the chuck is not a concern during that process

Last edited:

It's is a capacitor start motor. Correct. Once I get it up and running tomorrow night I'll connect it, then swap the black and white from what I had in the first photo and see what happens. Is that correct? The black and red wires that were on the motor when it was built are buried inside somewhere. Do you want me to see if they can be switched?