-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Servo running rough

- Thread starter matthewsx

- Start date

- Joined

- Jan 29, 2017

- Messages

- 311

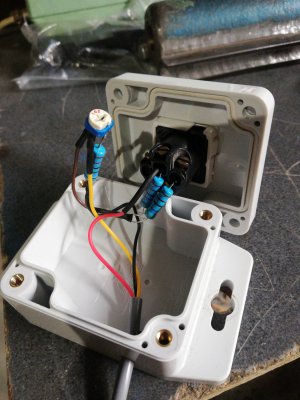

Finally got all my bits and pieces together along with my act and assembled this for my grinder motor controller.

As per Roberts schematic further back I knocked this up using the suggested resistors, with one change. I used a simple 102 trimpot instead of the C1K potentiometer he used. I adjusted the pot until my preset full speed came up on the fascia tacho and it ran.

Works great.

Resistors are sized 2 watt, the switch is a household light switch fitted to a small box from a local electronics store.

As per Roberts schematic further back I knocked this up using the suggested resistors, with one change. I used a simple 102 trimpot instead of the C1K potentiometer he used. I adjusted the pot until my preset full speed came up on the fascia tacho and it ran.

Works great.

Resistors are sized 2 watt, the switch is a household light switch fitted to a small box from a local electronics store.

Attachments

- Joined

- Jan 29, 2017

- Messages

- 311

- Joined

- Jan 29, 2017

- Messages

- 311

- Joined

- Jan 29, 2017

- Messages

- 311

John, i think your vibration is due to the timing belt itself. This type of belt really requires an idler pulley to tame it. My G0602 lathe came with one standard and I had the same problem which was causing a dirty surface finish. When I changed the motor to a dc treadmill version i machined the pulley teeth off and machined it to take a ribbed belt where the grooves run the length of the belt. I used the treadmill pulley on the motor.So I hooked up the belt and have the same issue, vibration above ~1500 rpm. I'm starting to think it may be an alignment issue or something to do with the mounting, it runs smooth as silk to ~2500 rpm without the belt and only vibrates a little at max 3000rpm.

I'm using the cast pot metal mount that came with the motor and when I play around with alignment it seems to move the vibration up and down in the rpm range. It's probably worth the effort to build a better mount with fine adjustment.

I'm also using a timing belt arrangement, maybe switching to v-pulleys with a round belt would be better?

John

Like a car belt. All vibration and chatter disappeared.

Cogged belts are fine for timing applications but I don't understand why the Chinese use them on lathes.

You should be ok with the original bracket. For driving a spindle go with a Vee or ribbed belt.

Cheers Alby.