- Joined

- Jan 20, 2021

- Messages

- 296

Quick fun project this afternoon.. the lathe chuck key handle was loose in the bore and always sliding out. The probe on the milling machine makes short work of locating the center of the bore. The Yuasa 5c indexer is really slick for rotating 90 degrees. Switch collets to drill a small dimple in the handle, still centered because of the indexer. The dimple gives the set screw a pocket to register in. Worked out well, it's on center and goes together quite nicely.

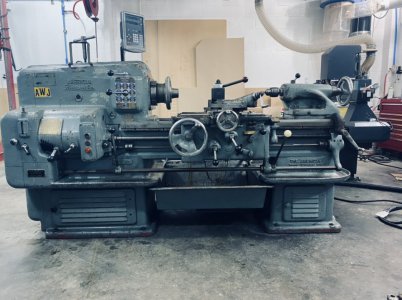

Cleaned up the tailstock and got it on the lathe. I'm really happy with the new lathe.

Cleaned up the steady rest. No more lathe cleaning for a while

I’ll store the steady rest on the end of the bed. I don’t have other storage sorted and I won’t be turning long parts often.

Cleaned up the tailstock and got it on the lathe. I'm really happy with the new lathe.

Cleaned up the steady rest. No more lathe cleaning for a while

I’ll store the steady rest on the end of the bed. I don’t have other storage sorted and I won’t be turning long parts often.

Last edited: