- Joined

- Jan 18, 2018

- Messages

- 314

First of all, why a mobile base? For me it is primarily for access to those things behind the lathe: the electrical box, coolant system, stored spare parts, etc. Also, it is nice to be able to pull the machine away from the wall and adjacent machines to allow long stock to extend from the spindle bore. It was very nice to be able to easily roll the lathe away from the wall when I installed a taper attachment and the coolant and guard systems as well as my tool holding systems, and sometimes you just want to clean up back there. So for me, there are a lot of reasons for a mobile base. All of my equipment can be moved, even my mill, but none seem to be as touchy to movement as a lathe so I wanted a system that would allow me to move the lathe without needing to spend a bunch of time re-adjusting it. It seemed like a pay-me-know-or-pay-me-later situation; spend the time now putting together a system that will allow me to move the lathe around without needing to re-adjust or spend the time later re-adjusting, or at least checking the adjustment, every time I moved it. The mobile base that I put together has three components:

1.) Outriggers with casters

2.) Machine mounts

3.) Baseplate

1.) Outriggers with casters

2.) Machine mounts

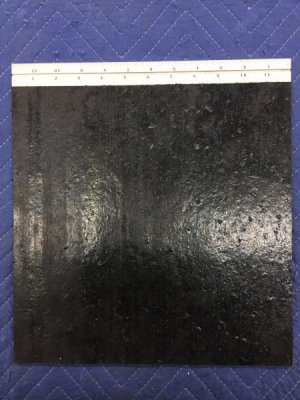

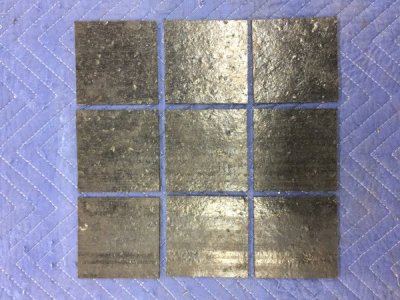

3.) Baseplate