“Leveling” and a Discussion on Vertical Miasalignment

First of all, my favorite work shirt is pictured above. I will explain this picture more fully later but for now let me just say that I might possibly be the only man alive that has set himself on fire leveling a lathe. More on this later.

For a newbie like myself the term leveling creates a lot of confusion; it really is an untwisting of the lathe ways that uses a level to accomplish the untwisting. I am going to quote John.K again from the beginning of this thread because he said it so well:

A lathe does not need to be level in any axis............it makes no difference to the accuracy..................however being level means an accurate level measurement tool can then be used to check for bending or twisting of the bed,and such corrected .......and later on used to check for wear...........

The untwisting ended up being much more straight forward than I anticipated but I would recommend a time when you are not in a hurry. Also make your changes in very small increments. Although I think I mentioned earlier that it took a quarter turn of the jack screw, my notes indicate that it was only a one eighth turn; so be patient. It’s pretty satisfying when you get it just right.

I did the alignment a couple of different ways. Many sources say to put a precision level directly on the ways. Well, this does not work with the PM 1236-T because the v-ways are a different height and the level is too far out of level to be useful. I think you can see this with this picture:

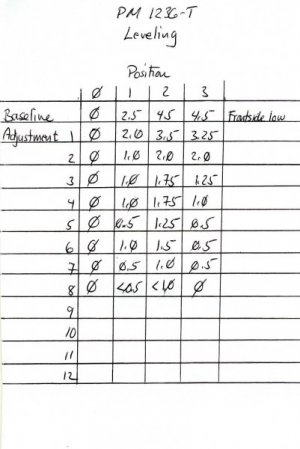

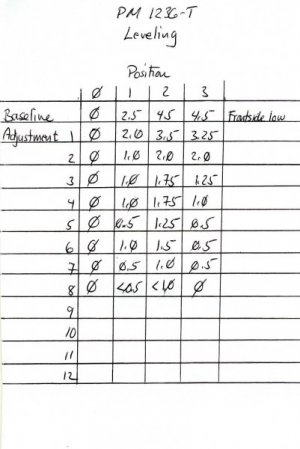

I decided to take the compound off the carriage and place the level on the carriage. I liked this approach because you are not repositioning the level, which can produce errors and since the carriage is what holds the tool in position and is ultimately what determines the height of the cutting tool. I placed tape on the the lathe at four evenly spaced intervals and took readings with the Starrett precision level by moving the carriage to each position using the carriage. I was careful not to let the level change position. It really is surprising how exquisitely sensitive the machine level is. These are the steps I took:

1.) level precision level using the leveler on the casters at the headstock end

2.) take readings at positions 1,2, and 3

3.) adjust the jack screw at the tailstock end

4.) back to step 1

Here is my set-up and my results:

You can see that it took eight tries to get it to where I felt I couldn’t get it any better, which was under 0.0005”/foot for the length of the bed. I am going to stop here for a bit. I have a very important date with a three year old to go to “Little Mermaid”. I will tell you about the shirt later today but just let me say that it is a lesson in “the enemy of good is better” .