- Joined

- Oct 4, 2016

- Messages

- 7,025

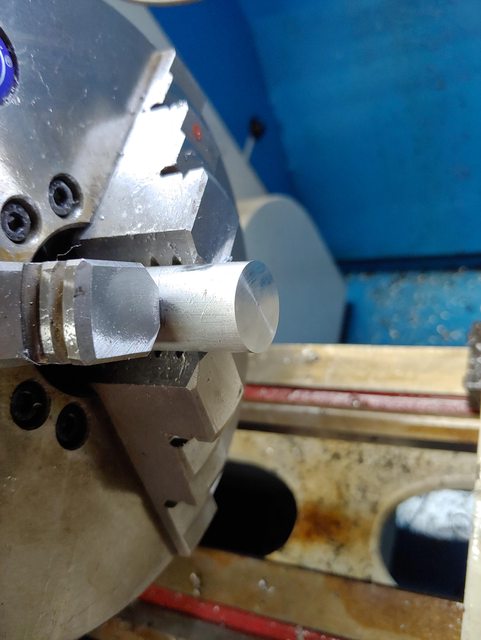

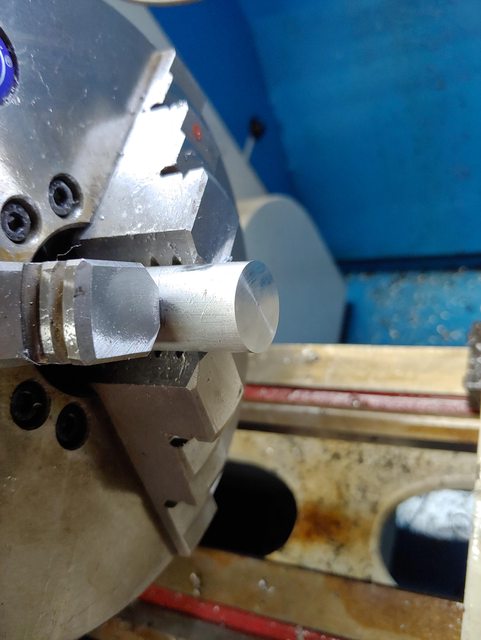

I think I'm closer to square, but may still be off height too. T 100 blade @ 500 RPM, set square, and height using the point of the dead center, and 1-2-3 block between the holder, and chuck. Right near center it does not want to advance, but with pressure it drops the piece with the nub on it. Just eyeballing with the machinist square, it's not completely flat.