- Joined

- Jun 12, 2014

- Messages

- 4,810

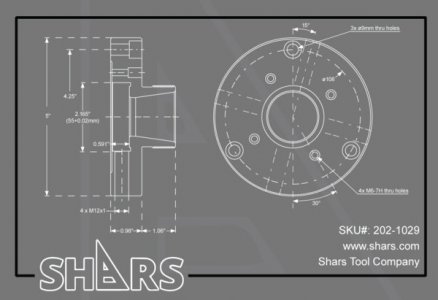

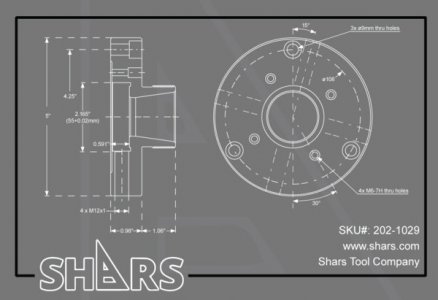

Wish this was around previously so I wouldn't have had to make my own set-true ER40. This is the first I have seen of a Set True or Set Fine adjustment style ER40 chuck from a manufacturer, and at a reasonable price. Should be easily to use different style back plates. Also see they now offer ER bearing nuts, although do not know the quality. FYI.

http://www.shars.com/5-er40-zero-set-fine-adjustment-collet-chuck

http://www.shars.com/er-40-ball-bearing-collet-nut

Works best on light cutting operation with easy to cut material such as aluminum or alloy steel

4 Fine adjustment screws on the side can be used to true up the chuck within 0.00005“ TIR repeatability

Collet chuck body is made from forged steel and precision machined

Compatible with standard ER40 collet which has a range of 1/8" to 1"

Max 6,000 rpm

Comes with 3 mounting bolts M8 x 70mm

Offer in plain back mounting with various threads size back plate or D series direct camlock mounting

http://www.shars.com/5-er40-zero-set-fine-adjustment-collet-chuck

http://www.shars.com/er-40-ball-bearing-collet-nut

Works best on light cutting operation with easy to cut material such as aluminum or alloy steel

4 Fine adjustment screws on the side can be used to true up the chuck within 0.00005“ TIR repeatability

Collet chuck body is made from forged steel and precision machined

Compatible with standard ER40 collet which has a range of 1/8" to 1"

Max 6,000 rpm

Comes with 3 mounting bolts M8 x 70mm

Offer in plain back mounting with various threads size back plate or D series direct camlock mounting