- Joined

- Jan 11, 2018

- Messages

- 308

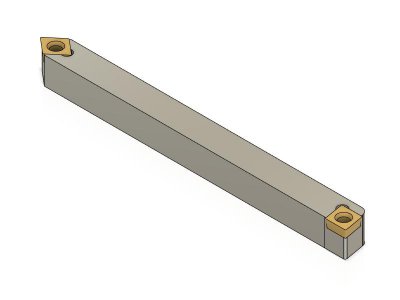

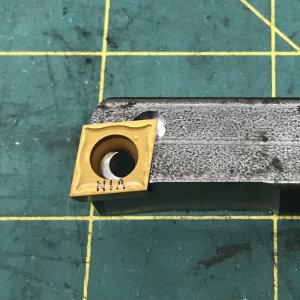

Here's another tool I'm considering based on some of the suggestions in this thread. This is a double ended CCGT tool. The turning side has the insert at a 40 degree lead angle for turning and chamfering. The facing side has the insert at a 0 degree lead angle. It might be better if it had a -5 degree lead so it could be used to face and turn to a journal.