I hope former Atlas owners are invited to post here! I miss mine!!

The choice between buying new machines, or old machines and fixing-restoring-repairing is often discussed here.

My first dedicated metal working machine (besides a drill press) was a Sherline Mill. I am so thankful to them for making machining possible to start.

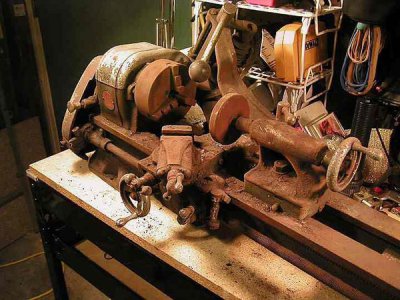

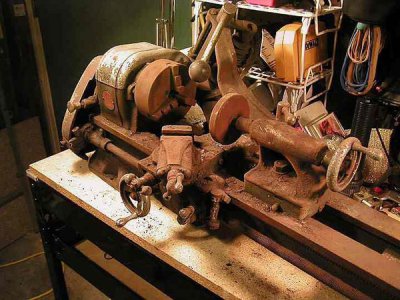

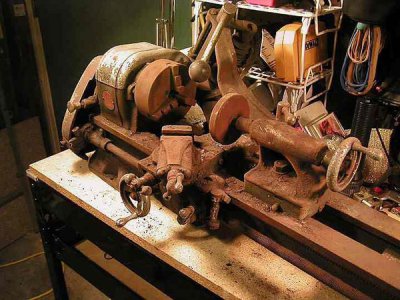

BUT I know I could have never really gotten started when I did, if I hadn't been given an old Atlas 618 it pretty ROUGH shape, and spent my time and elbow grease making it a wonderful machine. It is really pretty shocking to me looking at the condition it was in when I carried home:

... And let me be clear, I was thrilled! I spent all my "me" time for at least a month or two taking it apart, taking progress pics, cleaning every bolt and nut, slide, carefully polishing ways, and working stiff handles and controls all over. My friends also gave me the milling attachment, in similar shape. It was only missing change gears and a few little pieces to be complete under all the gunk, rust, dust, and overspray:

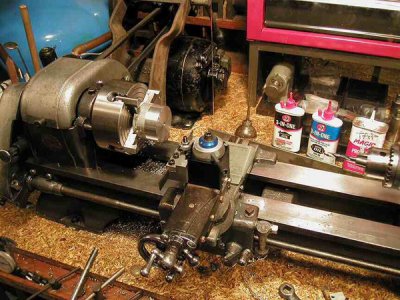

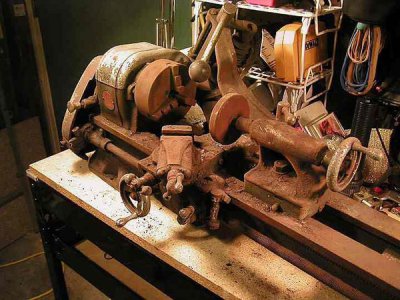

After a few months, and less than $75 on Ebay for miscellaneous parts, I had a wonderful, solid, and quite accurate machine that got me past the first few years of STEEP learning curve. That was nine years ago. I had this machine until recently. If I had NOT restored it, I would not have been able to get the South Bend Heavy 10 (10L for search purposes), since the time was right, I now had a worthwhile machine to SELL. If you can believe it, I got almost half of the money I needed for the SB by selling the Atlas 618 and it's accessories!! (I have more cool ones to sell by the way

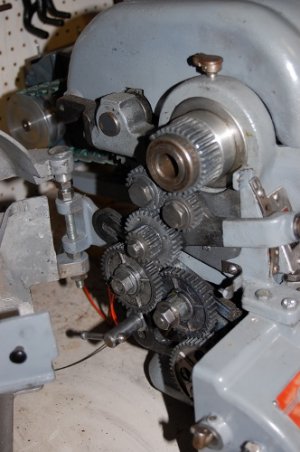

All the parts you can see there were the original parts!! Just cleaned up!! Even that leadscrew!

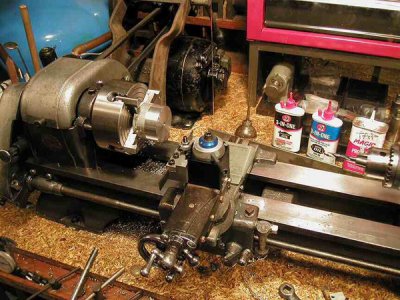

I traded a different machine for this really mint Atlas 618 too, and someone BABY'd it it's whole life- EXCEPT they painted it!! Why paint a mechanically perfect condition machine when you bought it new??? hah hah

He must have had fun painting it, because look how he labeled everything!

He even did an expert job retrofitting this handwheel at the end of the leadscrew for "micrometer carriage hand feed". I used this accessory daily when I owned this lathe!

He also did a nice job adding a GITS oiler to the leadscrew bearing:

I have all kinds of Atlas 618 and equivalent Craftsman literature digitized if anyone ever needs it.

Bernie