- Joined

- Oct 19, 2011

- Messages

- 127

IMHO, there's nothing wrong in posting a few "before" or "as received and/or bought" pics to give the viewer something to compare the pretty pics to. Just sayin. )

)

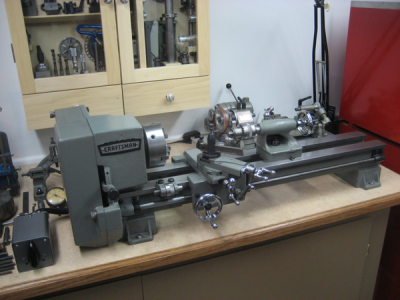

Here is my Craftsman 101.21200, it's little, but you can still do some good work with it. I bought it from the first owner who had most of the accessories for it. One of the reasons I wanted a MK1 or MK2 type 6" Lathe was because the Benchmaster mill I already had has a 2MT spindle, and I could share some tooling between them. I also already had a Unimat DB-200 with a A2Z quick change tool post that also can be used on either the Craftsman or Unimat. I placed a wanted ad on Craigslist and got a call about 1 week later and ended up buying it. Then I also got another reply for another MK2 lathe, and it happened to have some of the missing items I needed, so I bought that one too, and turned around and sold it for what I payed for it, minus what I needed of course