-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your Logan lathes!

- Thread starter HMF

- Start date

- Joined

- Jan 2, 2013

- Messages

- 4

- Joined

- Apr 12, 2011

- Messages

- 3,472

4

4GSR

Forum Guest

Register Today

I'm impressed of the number of Logn lathe owners out there!

- Joined

- Dec 28, 2011

- Messages

- 21

I might as well join the fun  A couple years ago, I helped my old neighbor clean out his garage. When we finally got to the back of the garage. There was a pile of iron and a bunch of boxes. I knew it was a lathe...just didn't know what make. I asked my neighbor what he was going to do with it and he said it was mine for giving him a helping hand

A couple years ago, I helped my old neighbor clean out his garage. When we finally got to the back of the garage. There was a pile of iron and a bunch of boxes. I knew it was a lathe...just didn't know what make. I asked my neighbor what he was going to do with it and he said it was mine for giving him a helping hand

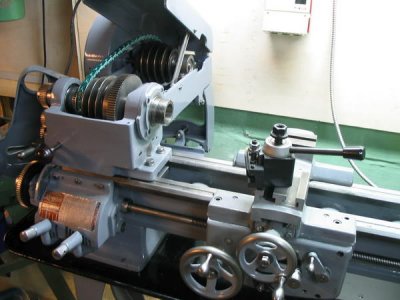

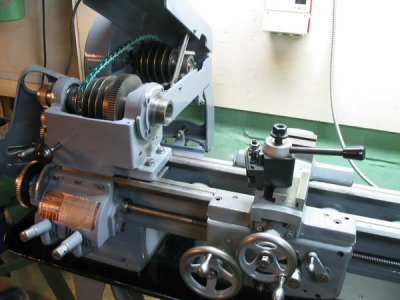

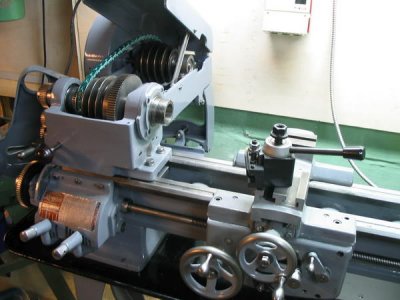

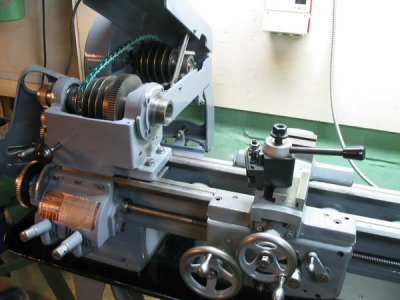

Anyway, it turned out to be a Logan 1922 (I believe). It was almost completely in pieces, dirty, parts missing. Luckily, the spindle bearings felt good and as it turned out , they were good I found the missing parts and basically rebuilt it. I wish I had taken photos of it in the barn....but I didn't. Anyway, here is the end result....

I found the missing parts and basically rebuilt it. I wish I had taken photos of it in the barn....but I didn't. Anyway, here is the end result....

I did install a VFD to run the original 3 phase motor and I did rebuilt the speed changer box and all the speeds do work, but, I use the vfd for speed changes. Later on down the line, I'll get a compound slide for it. I also would like to get the lathe to cut threads, just have to get a threading dial..someday

Anyway, it turned out to be a Logan 1922 (I believe). It was almost completely in pieces, dirty, parts missing. Luckily, the spindle bearings felt good and as it turned out , they were good

I did install a VFD to run the original 3 phase motor and I did rebuilt the speed changer box and all the speeds do work, but, I use the vfd for speed changes. Later on down the line, I'll get a compound slide for it. I also would like to get the lathe to cut threads, just have to get a threading dial..someday

- Joined

- Dec 30, 2011

- Messages

- 214

- Joined

- Nov 22, 2010

- Messages

- 371

Re: A " Kick Butt" logan....like No Other !

The world's "tallest Logan" circa 1942 ser # 15559 i t is rock solid and quiet. drive unit Mod was obviously well thought out and very well done.

Has taper attachment, lever tail stock, follower rest, Spindle threaded jacobs Chuck ( 1 1/2" x 8 threads) 5" 6 jaw Buck adjust-true Chuck 6" 4 jaw chuck, 1/2" jacobs with bronze floating jaws for working on electric motor comutators(?) on #2 taper plus std 1/2 " jacobs on # 2 taper. has Logans cast iron legs and chip pan all in fine condition. also has logan factory 'traveling Work light.

both bearings replaced approx 10 years ago. It's very very clean, Ways are excellent. It takes up a foot less space to the wall behind it. it has a 42 " +/- bed and it's available for sale or trade. more photos available upon request PM or contact via direct E-mail joebiplane@comcast.net

Joe

The world's "tallest Logan" circa 1942 ser # 15559 i t is rock solid and quiet. drive unit Mod was obviously well thought out and very well done.

Has taper attachment, lever tail stock, follower rest, Spindle threaded jacobs Chuck ( 1 1/2" x 8 threads) 5" 6 jaw Buck adjust-true Chuck 6" 4 jaw chuck, 1/2" jacobs with bronze floating jaws for working on electric motor comutators(?) on #2 taper plus std 1/2 " jacobs on # 2 taper. has Logans cast iron legs and chip pan all in fine condition. also has logan factory 'traveling Work light.

both bearings replaced approx 10 years ago. It's very very clean, Ways are excellent. It takes up a foot less space to the wall behind it. it has a 42 " +/- bed and it's available for sale or trade. more photos available upon request PM or contact via direct E-mail joebiplane@comcast.net

Joe

Last edited:

- Joined

- Oct 19, 2012

- Messages

- 456

Re: Some before and after pics of my 14 x 40 Logan

What did you use on the rust?

What did you use on the rust?