- Joined

- Feb 2, 2013

- Messages

- 3,627

I have a Deckel SOE clone grinder

(https://www.hobby-machinist.com/threads/kunming-kxm10-4-universal-cutter-grinder.59697/)

i wanted to use it for sharpening HSS blanks into precision carving instruments.

this would entail putting square HSS stock into a round collet.(because i don't have any square, imperial, deckel style collets)

A) i could purchase them, or B) i could spend way too many hours fixing a problem that had already been fixed by someone else , a lot smarter than i).

of course, i chose-B

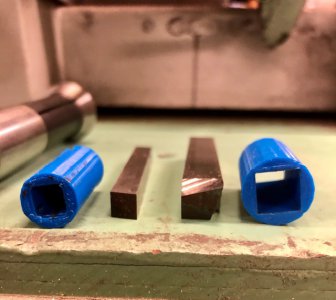

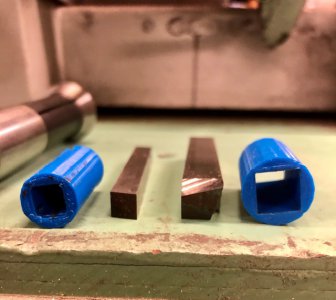

my idea was to design and test consumable 3D printed collet bushings in PLA, and utilize the bushings to sharpen HSS precisely

i designed 2 initial test collets. one for 1/4 square HSS and one for 3/8" HSS blanks

here are the results

i sharpened a 12° metal munching HSS tool in less than 10 minutes, that will shave the hairs from your arm!

The 3/8" bit collet fits into the 5/8" deckel collet

the 1/4" bit collet will fit the 1/2" deckel collet

the inspection on the 3/8 bit was good!(pictures were horrible)

i'll be doing the 1/4" bit next, then ??????

(https://www.hobby-machinist.com/threads/kunming-kxm10-4-universal-cutter-grinder.59697/)

i wanted to use it for sharpening HSS blanks into precision carving instruments.

this would entail putting square HSS stock into a round collet.(because i don't have any square, imperial, deckel style collets)

A) i could purchase them, or B) i could spend way too many hours fixing a problem that had already been fixed by someone else , a lot smarter than i).

of course, i chose-B

my idea was to design and test consumable 3D printed collet bushings in PLA, and utilize the bushings to sharpen HSS precisely

i designed 2 initial test collets. one for 1/4 square HSS and one for 3/8" HSS blanks

here are the results

i sharpened a 12° metal munching HSS tool in less than 10 minutes, that will shave the hairs from your arm!

The 3/8" bit collet fits into the 5/8" deckel collet

the 1/4" bit collet will fit the 1/2" deckel collet

the inspection on the 3/8 bit was good!(pictures were horrible)

i'll be doing the 1/4" bit next, then ??????

Last edited: