I was asking questions in a post about a manual but thought I would get a thread started to document my progress.

I picked up a Summit 19-4 x 60 lathe from a diesel performance shop that never got it hooked up because they didn't have 3 phase. It sat for at least 5 years and was backed into by a truck in the shop.

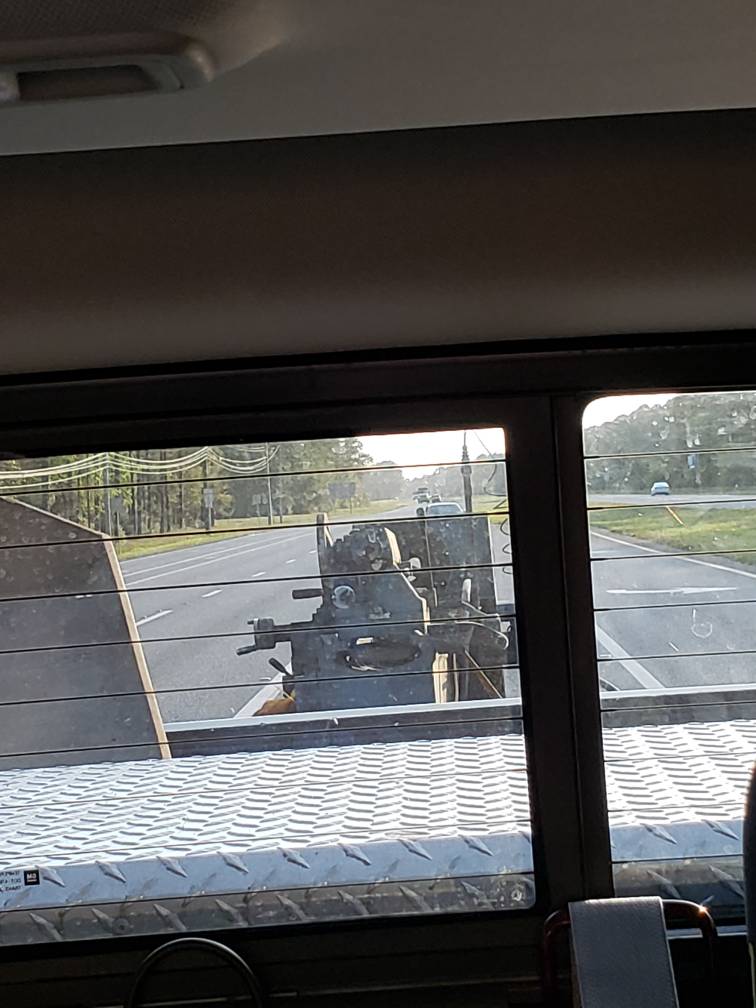

Here is the picture from the ad.

Sent from my SM-G960U using Tapatalk

I picked up a Summit 19-4 x 60 lathe from a diesel performance shop that never got it hooked up because they didn't have 3 phase. It sat for at least 5 years and was backed into by a truck in the shop.

Here is the picture from the ad.

Sent from my SM-G960U using Tapatalk