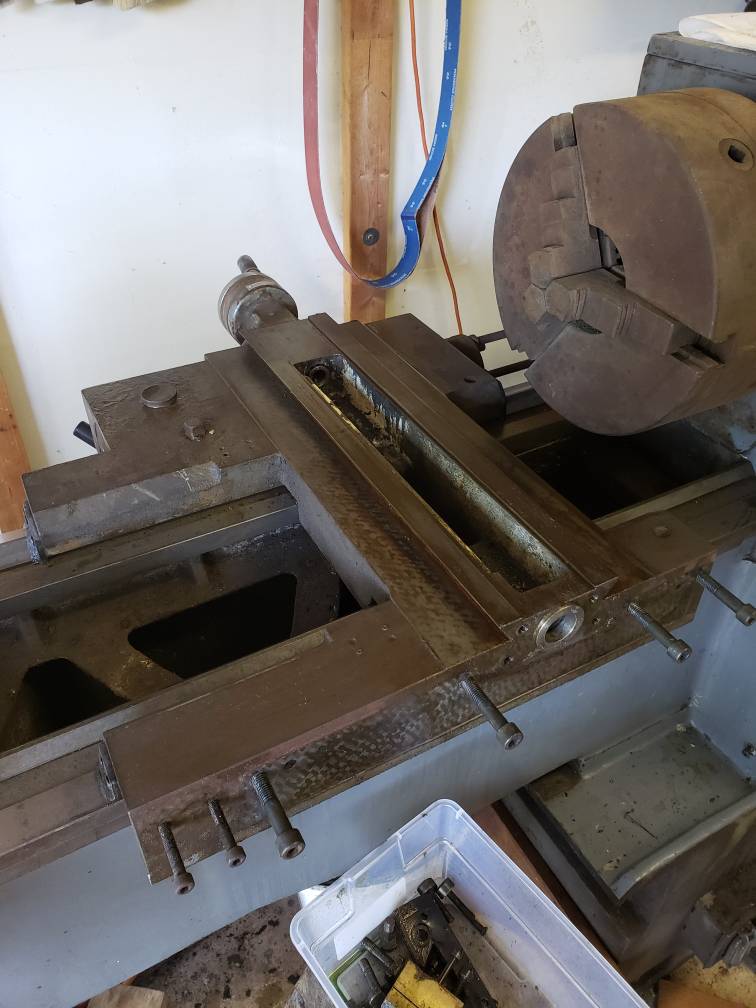

Yes, that and the spindle activation lever on the apron were both victims.I wish my lathe had a tailstock handle setup like that. What happen with the carriage hand wheel missing, victim to the accident?

Sent from my SM-G960U using Tapatalk

Yes, that and the spindle activation lever on the apron were both victims.I wish my lathe had a tailstock handle setup like that. What happen with the carriage hand wheel missing, victim to the accident?

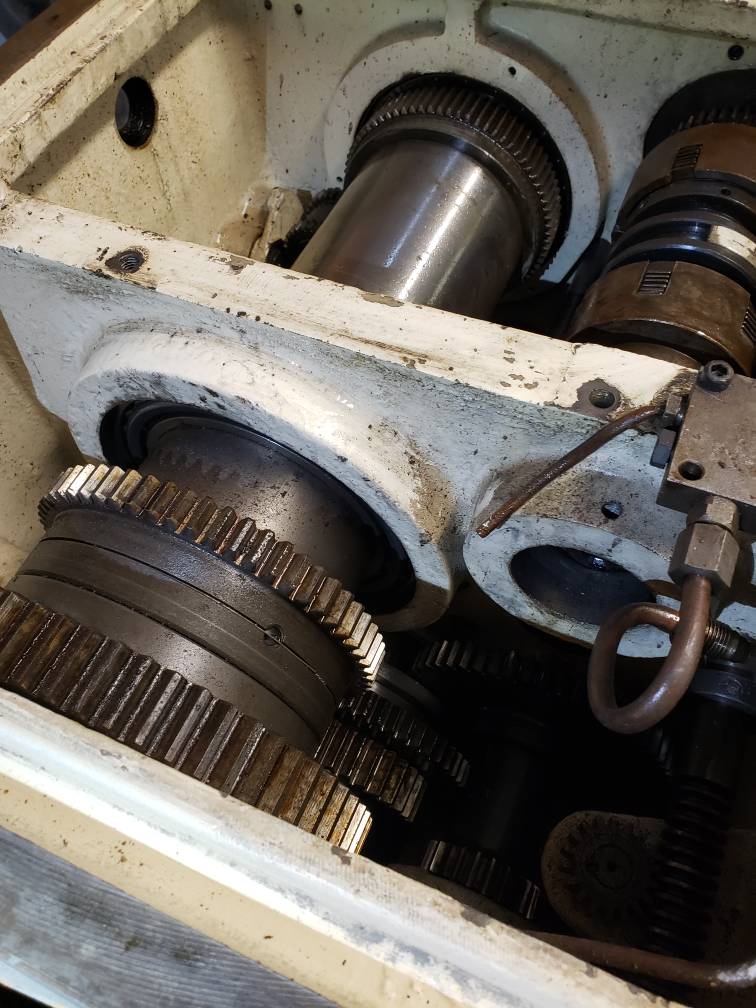

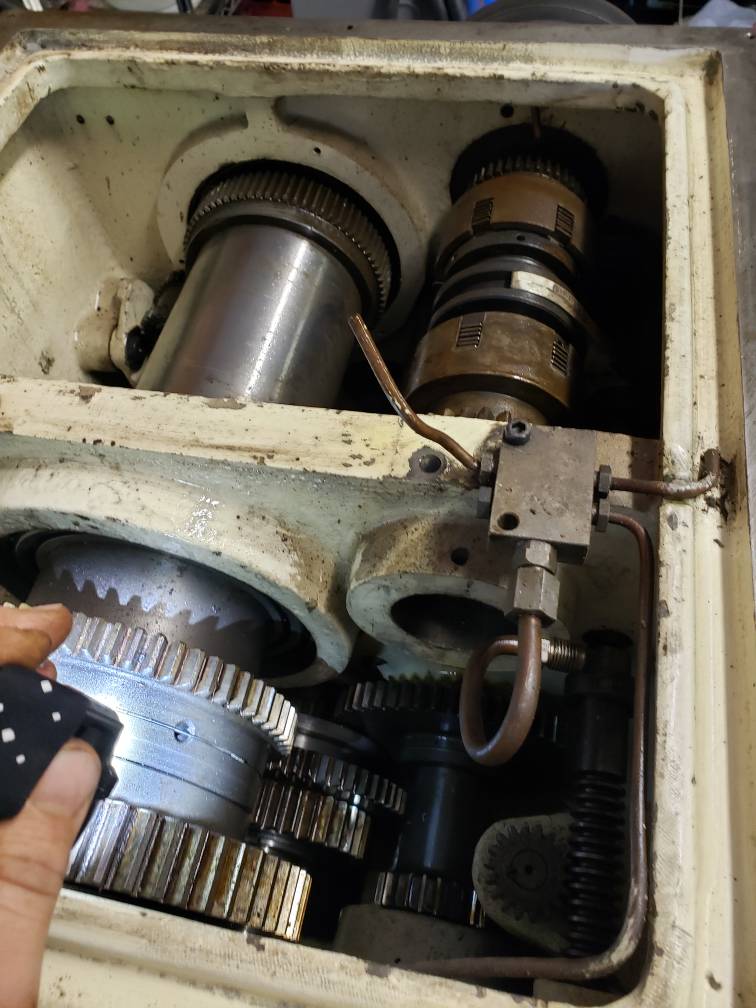

Thanks! I'll look at that. I didn't even look at the clutch because I had the belt removed.Mine has interlocks on the doors, they have to be closed and the clutch has to be in neutral to energize the motor.

Greg