-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tachometer Kits / Installs

- Thread starter TX COWDOC

- Start date

- Joined

- Jun 12, 2014

- Messages

- 4,810

Along the same lines, I just installed this one from Amazon in a recent build. At least the instructions were in English.

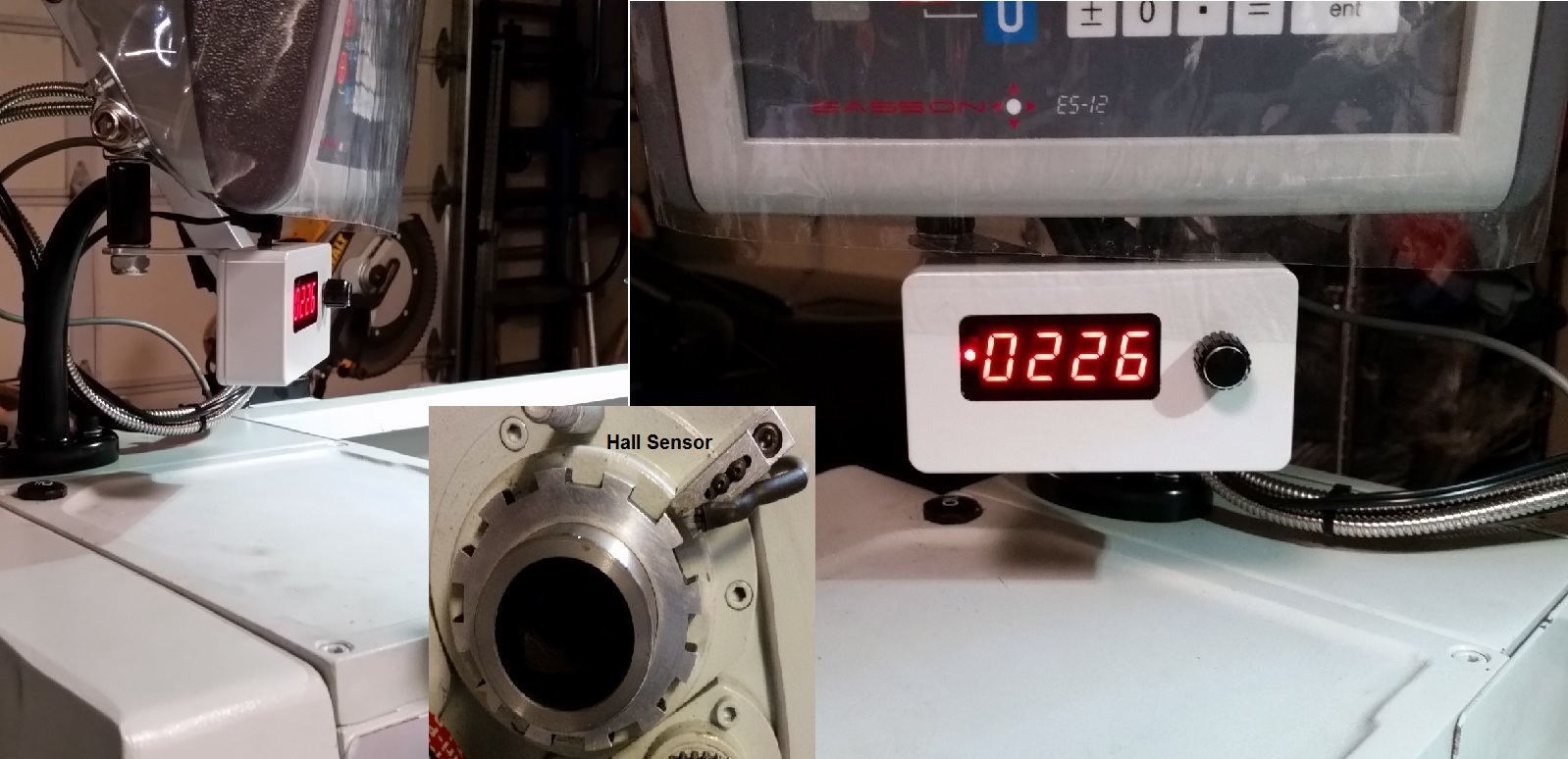

The VFD speed pot is integrated into the same Hammond Diecast box, I tap 2 holes in the back for mounting a L bracket. I typically mount these under the DRO if you have one, otherwise near the headstock away from flying oil and chips. RPM meter still has plastic covering on the display. Note that all these RPM gauge's hall sensor will only work with the correct magnet polarity, so mark the magnet as to the end that faces the hall sensor. You can check it by powering it up (can use a 9V battery) and then placing the magnet in front of the hall sensor and the LED light should flash on with the correct polarity. You can use electrical tape to temporarily hold the magnet to the spindle. Gap between the hall sensor and magnet is around 0.1-0.2", these use only one magnet. They are surprisingly accurate.

uniquegoods LED 4 Digital Tachometer RPM Gauge Speed Meter Tester 10-9999 RPM with Hall Proximity Sensor NPN Switch Red: Amazon.com: Industrial & Scientific

uniquegoods LED 4 Digital Tachometer RPM Gauge Speed Meter Tester 10-9999 RPM with Hall Proximity Sensor NPN Switch Red: Amazon.com: Industrial & Scientific

www.amazon.com

The VFD speed pot is integrated into the same Hammond Diecast box, I tap 2 holes in the back for mounting a L bracket. I typically mount these under the DRO if you have one, otherwise near the headstock away from flying oil and chips. RPM meter still has plastic covering on the display. Note that all these RPM gauge's hall sensor will only work with the correct magnet polarity, so mark the magnet as to the end that faces the hall sensor. You can check it by powering it up (can use a 9V battery) and then placing the magnet in front of the hall sensor and the LED light should flash on with the correct polarity. You can use electrical tape to temporarily hold the magnet to the spindle. Gap between the hall sensor and magnet is around 0.1-0.2", these use only one magnet. They are surprisingly accurate.

- Joined

- Dec 26, 2015

- Messages

- 2,079

Nice bench Mark. How about a YouTube tour with all your tool recommendations.

How hard is it to wire one of these in? I have decent electrical skills on big stuff i.e. wired my shop etc. but this is intimidating!Along the same lines, I just installed this one from Amazon in a recent build. At least the instructions were in English.

uniquegoods LED 4 Digital Tachometer RPM Gauge Speed Meter Tester 10-9999 RPM with Hall Proximity Sensor NPN Switch Red: Amazon.com: Industrial & Scientific

uniquegoods LED 4 Digital Tachometer RPM Gauge Speed Meter Tester 10-9999 RPM with Hall Proximity Sensor NPN Switch Red: Amazon.com: Industrial & Scientificwww.amazon.com

The VFD speed pot is integrated into the same Hammond Diecast box, I tap 2 holes in the back for mounting a L bracket. I typically mount these under the DRO if you have one, otherwise near the headstock away from flying oil and chips. RPM meter still has plastic covering on the display. Note that all these RPM gauge's hall sensor will only work with the correct magnet polarity, so mark the magnet as to the end that faces the hall sensor. You can check it by powering it up (can use a 9V battery) and then placing the magnet in front of the hall sensor and the LED light should flash on with the correct polarity. You can use electrical tape to temporarily hold the magnet to the spindle. Gap between the hall sensor and magnet is around 0.1-0.2", these use only one magnet. They are surprisingly accurate.

Can you post a pic of how you mounted it relative to the DRO? Many thanks!

- Joined

- Jun 12, 2014

- Messages

- 4,810

There are 2 wires for power which is typically 12VDC (about 50 mA), so need a small DC power supply or they have 24VAC to 12VDC step down converters that one can use power from your 24VAC transformer used for lights and the contactors. There are 3 wires used to connect to the hall sensor. They are all color coded and numbered so just connect the wires per the instructions.

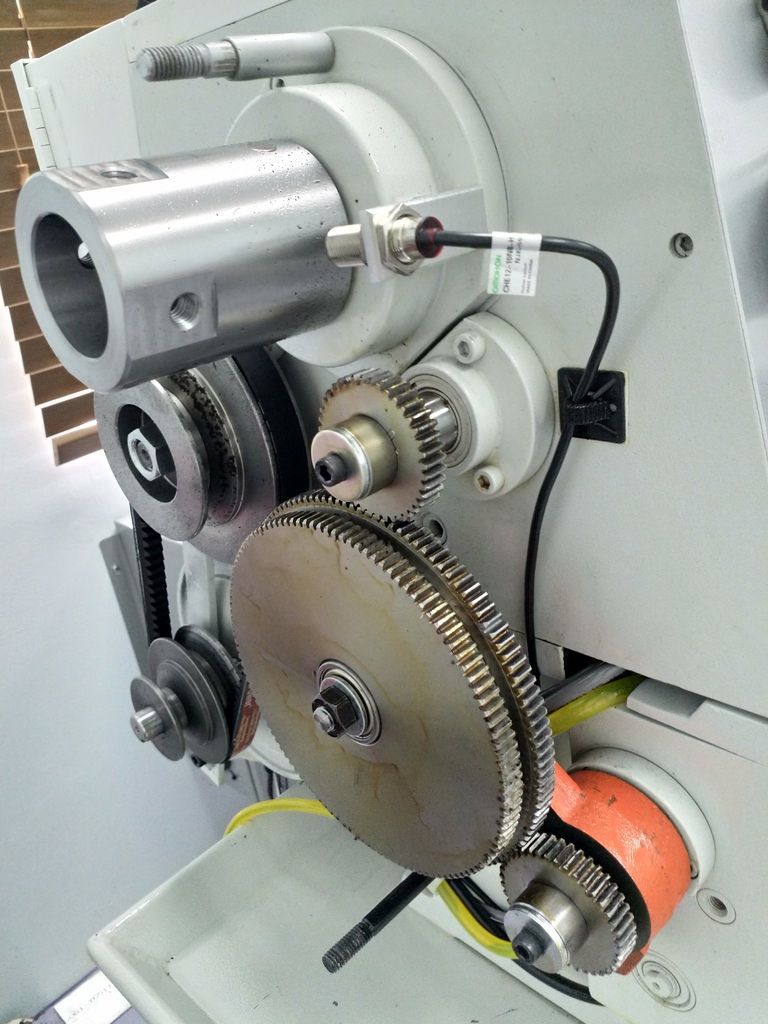

MachTach install, these kits are no longer available.

MachTach install, these kits are no longer available.

This handheld is in my cart for $15. I just need to check RPM periodically. https://www.amazon.com/gp/product/B004Q8L894/ref=ox_sc_act_title_2?smid=A1BREQ8I6OHSBG&psc=1

- Joined

- Feb 8, 2014

- Messages

- 492

There are 2 wires for power which is typically 12VDC (about 50 mA), so need a small DC power supply or they have 24VAC to 12VDC step down converters that one can use power from your 24VAC transformer used for lights and the contactors. There are 3 wires used to connect to the hall sensor. They are all color coded and numbered so just connect the wires per the instructions.

MachTach install, these kits are no longer available.

View attachment 337891

View attachment 337889

How in the HELL do you do work and keep your equipment that clean? I just spent 2 hours cleaning my lathe and it's still bad compared the this.

Here's the 2 parts I THINK will work. What wire size is needed to go from the machine to the converter? 12/2 romex? (This part is a joke  )

)

Amazon.com : Urban Security Group 24V AC to 12V DC Converter Adapter : 2.5A : Go from AC to DC Power : Input: 20-30VAC : Output: 12VDC 2.5A : Removable Terminal Block : Full Wave Rectifier : Camera & Photo

Amazon.com : Urban Security Group 24V AC to 12V DC Converter Adapter : 2.5A : Go from AC to DC Power : Input: 20-30VAC : Output: 12VDC 2.5A : Removable Terminal Block : Full Wave Rectifier : Camera & Photo

www.amazon.com

DIGITEN 4 Digital Green LED Tachometer RPM Speed Meter + Hall Proximity Switch Magnet Sensor NPN for Lathe Conveyor Belt: Amazon.com: Industrial & Scientific

DIGITEN 4 Digital Green LED Tachometer RPM Speed Meter + Hall Proximity Switch Magnet Sensor NPN for Lathe Conveyor Belt: Amazon.com: Industrial & Scientific

www.amazon.com

- Joined

- Jun 12, 2014

- Messages

- 4,810

Wire is only carrying about .050A so use 18 or 20AWG. This is from the 24VAC (not 204VAC), wire to the converter and then from there to the input power of the tachometer. The Hall sensors are wired slightly different, essentially a negative and positive power, and a wire that electrically sends a pulse open to closed when the magnet is in front of the hall sensor. Wires to the hall sensor take about 10 mA, you can use anything from 18-22AWG, nothing special.