- Joined

- Sep 1, 2023

- Messages

- 70

After ordering a set of turning carbide insert holders and noticing a defective one (the insert would simply not screw into place), I did another attempt before giving up, with another seller, and received a set that was even worst.

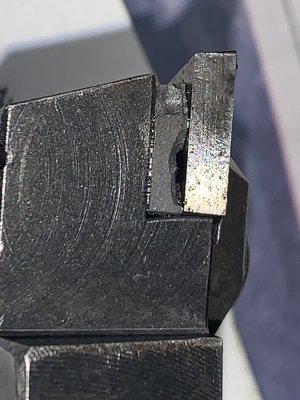

3 out of the 7 holders in the set had a gap greater than 0.1mm under their tip, I was able to slide a 0.1mm feeler gauge under it, I have attached a photo to illustrate the issue.

The nice thing about SCamazon, is that items can be returned at no costs, so there is only loss of time, but in my case the time spent was a good learning opportunity.

I realise that holders are more difficult to fabricate than I thought, the bearing surfaces under the insert needs have maximum contact, if you have a fraction of the surface that is in contact, you will get that fraction of the rigidity.

The fact that heat hardening can introduce distortion, adds another level of complexity, I suppose the only way to guaranty maximal contact surface is to have grinding as a last step.

I've have ordered holders from a seller that is higher in the food chain, not a top name brand, but one that has a name a reputation that is worth preserving. I also ordered others from an ebay seller that was praised on this site, I'll be doing a bit of "metrology" before I even put them to use.

Feeler gauge test, perhaps a test with Prussian blue, if the contact surface is decent it's a good start, as for hardness test, I wish I had a Rockwell hardness tester !

3 out of the 7 holders in the set had a gap greater than 0.1mm under their tip, I was able to slide a 0.1mm feeler gauge under it, I have attached a photo to illustrate the issue.

The nice thing about SCamazon, is that items can be returned at no costs, so there is only loss of time, but in my case the time spent was a good learning opportunity.

I realise that holders are more difficult to fabricate than I thought, the bearing surfaces under the insert needs have maximum contact, if you have a fraction of the surface that is in contact, you will get that fraction of the rigidity.

The fact that heat hardening can introduce distortion, adds another level of complexity, I suppose the only way to guaranty maximal contact surface is to have grinding as a last step.

I've have ordered holders from a seller that is higher in the food chain, not a top name brand, but one that has a name a reputation that is worth preserving. I also ordered others from an ebay seller that was praised on this site, I'll be doing a bit of "metrology" before I even put them to use.

Feeler gauge test, perhaps a test with Prussian blue, if the contact surface is decent it's a good start, as for hardness test, I wish I had a Rockwell hardness tester !