-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1935 Craftsman/Walker-Turner 15 Inch Drill Press Mystery

- Thread starter CPO Ted

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,532

I was thinking that, or maybe it's from a powered utility cart or a very small tractor or tiller or something. Really ingenious.Could be a ring and pinion off of a car differential?

Cutting oil is my blood.

I could be way off, but those gears and pulleys have a very agricultural look about them. Belt driven mower maybe. Right angle drive for a direction change, and bolted hub pulleys for speed/horsepower adjustment... I dunno...

I wonder how much torque they were getting out of that little bugger to feel it necessary to weld the top collar directly to the drill chuck body? Sure enough it won't work loose that way...

I wonder how much torque they were getting out of that little bugger to feel it necessary to weld the top collar directly to the drill chuck body? Sure enough it won't work loose that way...

The space inside the cast-in pulley guard is pretty small, a lot smaller then would seem given this photo. From the edge indicated by the arrow to the corresponding edge on the other side is only about 5 1/2 inch or just a little more. My guess is that gear is probably about 4 inches in diameter.

By my eye, whoever put this together ground off 1/2 of the biggest pulley (#4) and bolted the gear onto the next pulley (#3) down.

By my eye, whoever put this together ground off 1/2 of the biggest pulley (#4) and bolted the gear onto the next pulley (#3) down.

- Joined

- Mar 10, 2013

- Messages

- 1,428

It isn't that large and heavy like a car differential would be.Could be a ring and pinion off of a car differential?

Cutting oil is my blood.

Dave

BTW Dave ... thank you for sharing this DP ... VERY interesting. And GREAT pictures!It isn't that large and heavy like a car differential would be.

Dave

The idea of using automotive parts is a good one, Since 1976 I have owned a LOT of MGBs and used parts from them on any number of non-automotive projects.

Thinking that the reducer project was done "back in the day" when the most common of automobiles was the Model T Ford. The engine of of the Ford only put out 22 HP., so it's a pretty good place to start looking. I spent some time trying to find out what I could about the gears in the T's differential. A 40 tooth Model T ring gear (crown wheel) is a straight cut gear having an od of 8.100" and an id mounting diameter of 5.248". The threaded mounting holes are on a 5 13/16" bolt circle. It is too big by a bunch.

Additionally, most, but not all, automotive differentials use ring gears that are hypoid gears rather than straight cut for greater strength and quieter operation. I suspect that farm tractors are much the same. When I began my career as a mechanic back in the early 19 and 70s, I took a job at a International Harvester & Checker Automobile dealership. One thing I remember about farm tractors is that every thing on it is big and very heavy ... except maybe PTO stuff.

Maybe something like the old (very old) International Cub Cadet would be a good donor, but, as far as I remember, they didn't come along until the 1960s.

Based on all of this, I think I would be inclined to look at PTO drives on farm stuff, and shafts that drove cutting blades of some type.

Last edited:

- Joined

- Mar 10, 2013

- Messages

- 1,428

all the 900 series WT have the tag on the front of press and mine has the nice oval brass tag on the left side and has no serial number on it.Hey Dave ...

I just did a quick check of the 1934, 1935 and 1936 WT manuals. Unless I am over looking something, I do not see the speed reducer you have on your machine listed as an option or as "parts" in any of the catalogues listed from that time. I checked anything to do with pulleys, motors and belts and could not come up with anything with a gear on it.

This speed reducer is very interesting to me for a number of reasons. The shaft pulley is a pretty special item because of the way its mounted into the top of the casting. Coming up with that gear to bolt on is pretty amazing. Additionally, coming up with a means of supporting the "main shaft" as well as aligning the two gears Is pretty sophisticated for a guy in his basement shop. I can't but help think that this is some sort of kit or something that came off another machine rather than something put together with catalogue parts.

Again, I could be wrong. Hopefully someone having better information than I could come forward.

As for the drill press itself, based on an examination of the various WT catalogues from 1933 to 1939, I find that the cast in pulley guard having a "right side up bowl" appearance accmodating the largest sheeve of a multisheeve pulley as seen on your machine only appears on those Walker-Turner Driver-line series 900 machines sold in 1934 and 1935.

I do have another

the space on my WT between your arrow and other inside casting is 6 inches. the gear is 5 inch diameter.The space inside the cast-in pulley guard is pretty small, a lot smaller then would seem given this photo. From the edge indicated by the arrow to the corresponding edge on the other side is only about 5 1/2 inch or just a little more. My guess is that gear is probably about 4 inches in diameter.

By my eye, whoever put this together ground off 1/2 of the biggest pulley (#4) and bolted the gear onto the next pulley (#3) down.

View attachment 422650

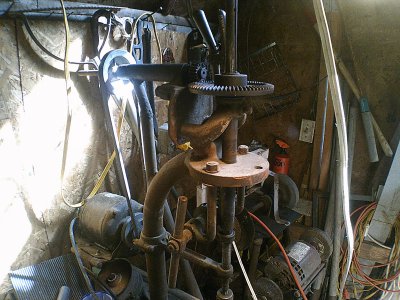

I took some pictures of my old vintage bench drill press that uses a gear drive also. ring gear is on the bottom. It's ring gear is 6 inch diameter. it has a perfect ratchet feed handle to always be able to adjust to pull down for pressure and a small 4 way handle on the orher side. I don't know the brand name of mfg. co. or if it was totally hand made in someones' shop. I know that I can drill through a 1" iron plate with a 1" drill bit in quick time with all the down pressure you have available. these old vintage drill presses are sure fun to have. enjoy looking at them.

Dave

Dave

Attachments

-

DSCF0001.JPG665.5 KB · Views: 12

DSCF0001.JPG665.5 KB · Views: 12 -

DSCF0002.JPG628.6 KB · Views: 10

DSCF0002.JPG628.6 KB · Views: 10 -

DSCF0005.JPG713.9 KB · Views: 11

DSCF0005.JPG713.9 KB · Views: 11 -

DSCF0006.JPG848.8 KB · Views: 11

DSCF0006.JPG848.8 KB · Views: 11 -

DSCF0007.JPG682.1 KB · Views: 11

DSCF0007.JPG682.1 KB · Views: 11 -

DSCF0008.JPG654.2 KB · Views: 10

DSCF0008.JPG654.2 KB · Views: 10 -

DSCF0009.JPG696.6 KB · Views: 10

DSCF0009.JPG696.6 KB · Views: 10 -

DSCF0010.JPG670.7 KB · Views: 10

DSCF0010.JPG670.7 KB · Views: 10 -

DSCF0011.JPG798.6 KB · Views: 12

DSCF0011.JPG798.6 KB · Views: 12

Dave,all the 900 series WT have the tag on the front of press and mine has the nice oval brass tag on the left side and has no serial number on it.

I do have another

Dave

As I mentioned in my article, Walker-Turner did not begin putting ID tags on their machines until 1939. After that date W-T machines had the serial or part number tags installed on their base, in front of the column. Eventually WT may have started putting the number on that nice brass tag, but I have no information about that.

I LOVE old cast iron tools. Apart from my table saw, band saw and hand held electric drills, saws and grinders, that's what you'd find in my basement shop. Both of my sewing machines are old Singers, one from 1952 the other is older than that ... and both run wonderfully.

We used to make great stuff in this country. Strong, durable and reliable. I'll pass my Craftsman/WT drill press (and my Buffalo No 18 drill press and my Craftsman/Atlas lathe and the rest) on to my son ... and I KNOW he'll be able to pass it on too.

- Joined

- Sep 1, 2018

- Messages

- 648

Think still have my BTO 8 track tape. KLAZ fm in Little Rock played their stuff a lot.