- Joined

- Jan 6, 2017

- Messages

- 1,214

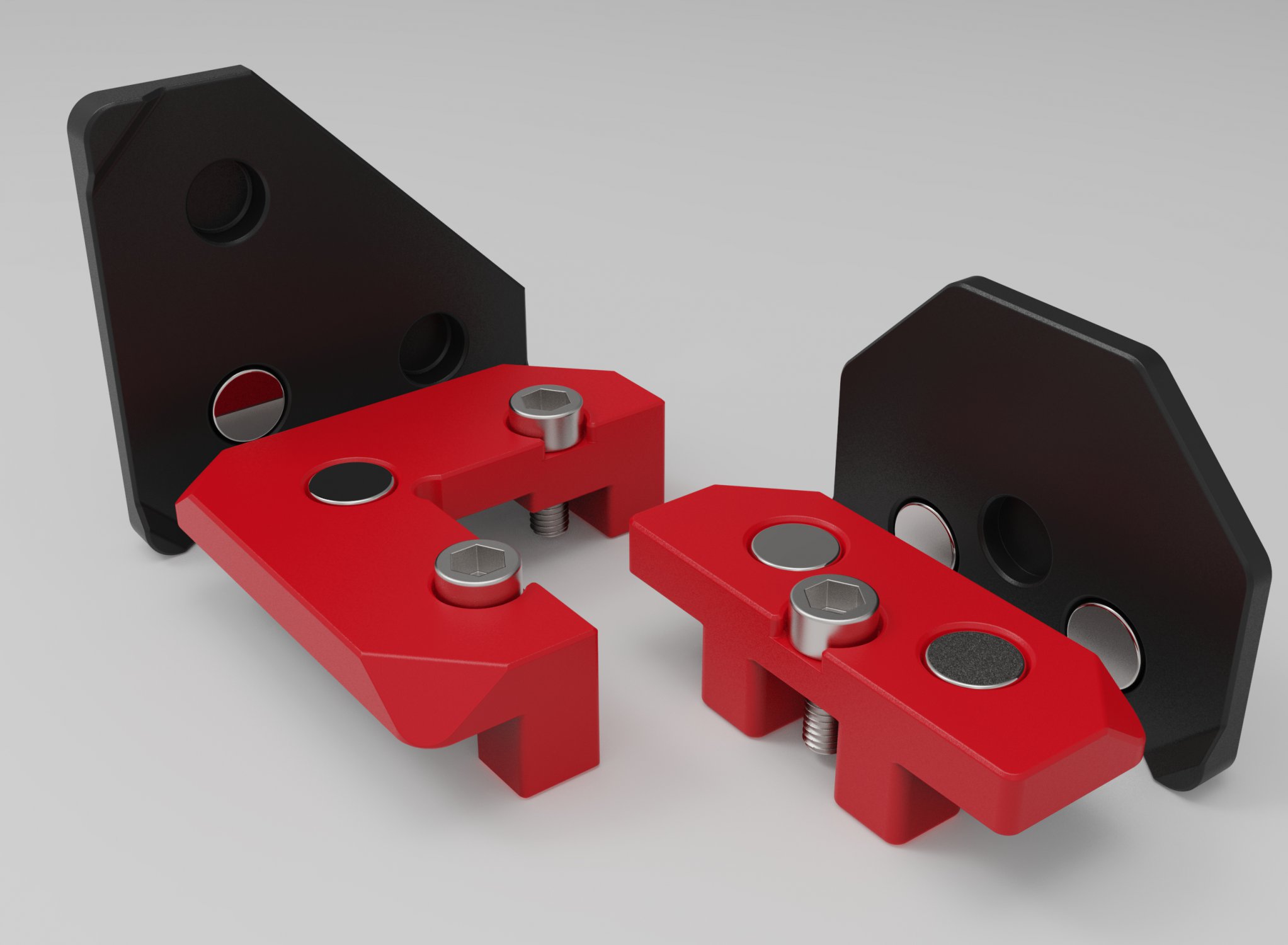

After lots of trial and error, i came up with a magnetic panel clip design that's working for me.

Instead of the upper underside horizontal face bearing against the 2020 rail, all of the force is applied by the pillars, downward against the inside of the t-slot. It prevents the clip from being pulled into the channel by the screws and lifting the rear edge.

They work really well.

The downside is that they are a little tougher to install than other types. The hammerhead screws have to be positioned into the slot, and rotated 90 degrees before the clip can be positioned over it.

www.printables.com

www.printables.com

Instead of the upper underside horizontal face bearing against the 2020 rail, all of the force is applied by the pillars, downward against the inside of the t-slot. It prevents the clip from being pulled into the channel by the screws and lifting the rear edge.

They work really well.

The downside is that they are a little tougher to install than other types. The hammerhead screws have to be positioned into the slot, and rotated 90 degrees before the clip can be positioned over it.

Printables

Last edited: