Here's a link to the one I have. I bought an extra probe tip and a couple of other things too. Just ran a check on a 3/8" shaft, Tormach interface, combo ETS/probe, standard 2" long 1/8" diameter probe at $132.40. I can't find a copy of my invoice, but probably paid $160 or so with the extras.

I did remake one part of mine. The body of the probe is 2 pieces of aluminum, I'll call them the body and the attaching plate. Those two thread together. Mine only had about 1/8-turn of thread engagement, granted, on a 2+' diameter. I'd learned to rotate the probe in the spindle clockwise to always tighten the body into the attaching plate. That is after turning it CCW a few times and having the body and top plate spring apart. I turned a new top plate with better thread engagement, but still turn it CW so the body is always tightening into the top plate.

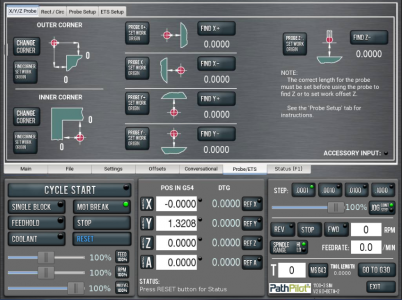

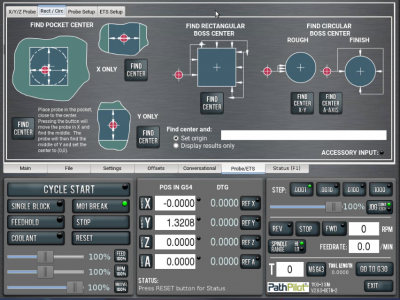

I don't use mine as a tool setter as I have a Tormach ETS. To use the econoprobe as an ETS, you unscrew the probe tip and screw in a touch plate. You also have to remove the mounting shaft that goes to the top plate. You could make a table mount adapter that would allow the TTS tool holder to drop into (like the Tormach surface plate with the hole in it for tool measurements). Then just unscrew the tip, screw in the plate, and set the probe upside down in the adapter to save a step.

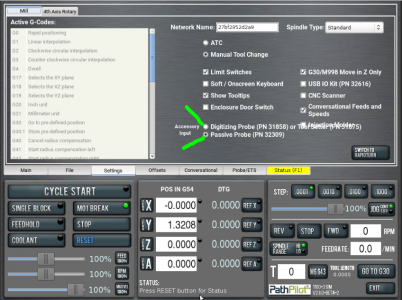

The cumbersome thing in my current set up is the probe and ETS logic are reversed, one is Normally Open, other is Normally Closed. I have to go to the setting tab to change between the two before probing or using the ETS. Frankly, for a onesie tool measurement, I've found it quicker to manually measure the tool length on the Tormach surface plate and height gauge. The height gauge has a USB plug to directly dump the measurement into the tool offset table, but I just manually type the number in. An advantage of using the Econoprobe for both would be not having to change the settings between NO & NC logic.

Not to belabor it (but too late. . .), Millfast Products makes a box for around $100 that auto-switches between the two logic states. Advantage would be my ETS and passive probe could both be plugged into the controller and I wouldn't have to fiddle with the switch logic in the settings menu. I have one of their remote E-stops on my 1100 and would love to get the switch box but they have been out of stock since before Christmas and don't respond to emails.

Bruce