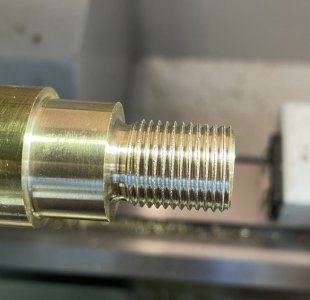

That looks better than my first attempt!

I see what you mean about the "double peak". Is it possible that the feed lever was engaged on the wrong number on the threading dial early on during a shallow cut?

A few questions.

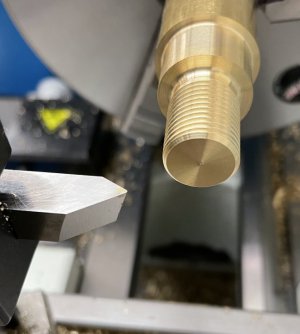

1) what tool are you using? HSS? carbide insert ? Pictures of the tool would help.

(no top rake and no cutting fluid is typical for brass)

2) what size and type of lathe? Is there much wear in the cross and top slide screws/nuts? I want to get a feel for size and rigidity of the machine.

(EDIT: never mind, I re-read and see a new PM machine!)

3) What technique? are you plunging straight in with the cross slide, or setting the top-slide/compound to 30 degrees from perpendicular and feeding with it?

It is fairly standard practice to finish threads with a wire brush and a flat file to help clean the threads while still on the lathe.

Just watch for those chuck jaws, and never use a file on the lathe without a handle.

Brian