-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Nov 17, 2017

- Messages

- 1,525

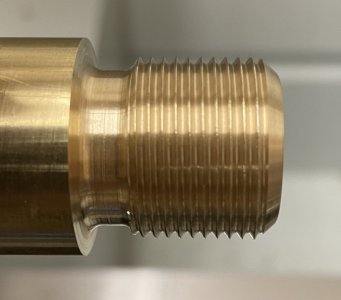

Looks to me like the scratch pass was on a different 'number' than the rest of the passes. To carries on the entirety of the threads.

you can see the nose radius on the tool.

you can see the nose radius on the tool.

- Joined

- Jun 7, 2013

- Messages

- 10,142

I use Aloris threading tools, on the small ones I stone a small flat on the point, on the larger ones, I surface grind a larger flat in line with the amount of flat used on commercial fasteners of comparable pitch.

- Joined

- Dec 31, 2010

- Messages

- 937

Is it possible that the threading dial was not fully engage in the lead screw? J like @Mr. Whoopee's suggestion about eliminating backlash.

Have a good day

Rock Breaker

Have a good day

Rock Breaker

- Joined

- Jun 7, 2013

- Messages

- 10,142

I was taught that drag on the handwheel in high school/JR college shop to clean up the backside of the thread on the last spring passes, we also used the tried and true 30 degree setting of the compound, rather that the revisionist 29 1/2 degree setting that so many seem to think is better; as I have said before, all the journeymen in my apprenticeship shop used the 30 degree setting.It can also help to put some drag on the handwheel with one hand to take up any play.

- Joined

- Mar 21, 2018

- Messages

- 1,606

Also look up the correct geometry for a threading tool. There should be some top rake on it.

Also, on a lot of lathes, you can engage the half-nuts on any mark for an even number of threads (you'll have to check your lathe to see if it is true with yours too).

Also, on a lot of lathes, you can engage the half-nuts on any mark for an even number of threads (you'll have to check your lathe to see if it is true with yours too).

- Joined

- Jan 25, 2022

- Messages

- 110

- Joined

- Jan 20, 2018

- Messages

- 5,672

That looks MUCH better! It almost looks like you know what you're doing.Confirming this group's suggestions, it appears I was catching the engagement just before the desired number, probably more than once. There are three engagements between the major divisions, and it is easy to engage the early one. Lessons learned, and thanks again !

View attachment 400814

- Joined

- Jan 25, 2022

- Messages

- 110

Almost  . Actually, thanks !

. Actually, thanks !

Going to try some knurling on that brass piece, after I figure out how to set the diameter for the knurl pitch.

Next: steel. Enjoyed grinding the tools for brass. Steel tools seem a bit more complicated.

K

Going to try some knurling on that brass piece, after I figure out how to set the diameter for the knurl pitch.

Next: steel. Enjoyed grinding the tools for brass. Steel tools seem a bit more complicated.

K