- Joined

- Aug 14, 2011

- Messages

- 101

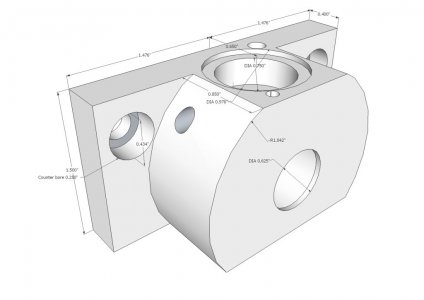

Yet another error has crept into my drawings. The original drawing called for a bore diameter of 0.550" for the eccentric bushing when in fact the bore for bushing itself should be 0.750". The following drawing is corrected. Sorry for the confusion.

Diagram #1 - Front view of the main body.

Regards,

Jim

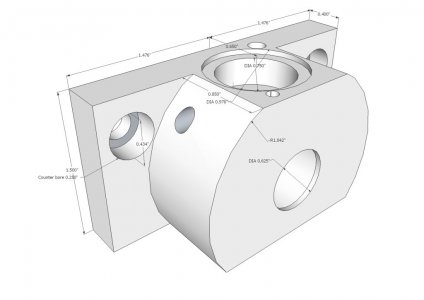

Diagram #1 - Front view of the main body.

Regards,

Jim