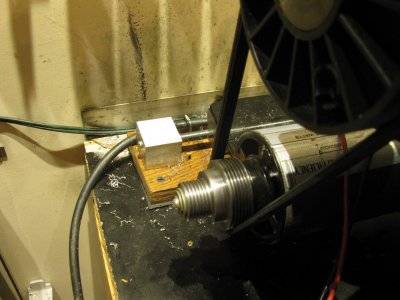

Mine looked the same. Probably no point taking it off, at least that's what I concluded... any V-belt will require a larger pulley than the poly-V belt used anyway. What I did was to bore out a standard V-belt pulley to slip over the existing pulley, and locked it into place with the new pulley's set screws (I filed a flat for the set screw onto the old poly-v grooves). Worked perfectly:

There are a few "treadmill conversion" threads here with varying amounts of information, but I thought I'd summarize my own experiences here in one single thread as I progress. As of this writing, it's still a work in progress: I've wanted for awhile to convert my Jet 15 mill/drill to a...

www.hobby-machinist.com