-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[How do I?] Turn accurate parallel faces on a disk

- Thread starter NC Rick

- Start date

Nice! What collet size is it, to grab the bottle cap to pull it off?Protect is finished! Thanks guys.

View attachment 343317

- Joined

- Jul 31, 2020

- Messages

- 765

All that work to open a beer bottle; WOW machinist just love making gizmos for the heck of it

- Joined

- Feb 17, 2013

- Messages

- 4,406

All that work to open a beer bottle; WOW machinist just love making gizmos for the heck of it

Adam Savage's One Day Builds: Overengineered Bottle Opener w/ Laura Kampf! - Tested

The amazing Laura Kampf visits Adam's workshop for a new One Day Build collaboration! Their plan: design and build an overengineered bottle opener that can slam the cap off of a standard glass soda bottle. After much trial and error, behold the Kampf bottle opener!

www.tested.com

www.tested.com

- Joined

- Nov 23, 2014

- Messages

- 2,607

I wondered what he was doing after MythBusters. Watched White Rabbit with Tory, Grant and Kari on Netflix, but not the same as the original show.

Adam Savage's One Day Builds: Overengineered Bottle Opener w/ Laura Kampf! - Tested

The amazing Laura Kampf visits Adam's workshop for a new One Day Build collaboration! Their plan: design and build an overengineered bottle opener that can slam the cap off of a standard glass soda bottle. After much trial and error, behold the Kampf bottle opener!www.tested.com

- Joined

- Feb 17, 2013

- Messages

- 4,406

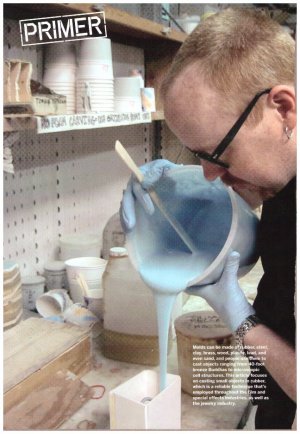

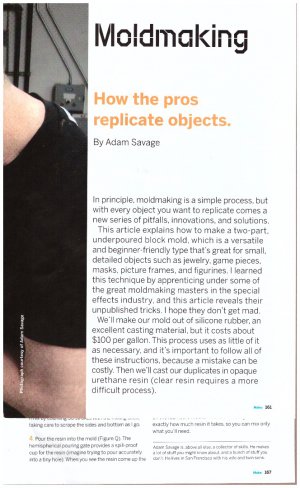

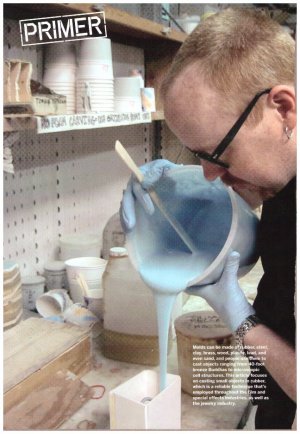

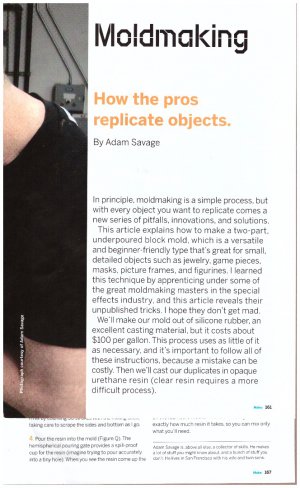

Adam has done some TV stuff, usually for kids, and he's been making a large number of videos in his shop and posting them on Tested. Coincidentally, last night I was trying to impose some organization on my collection of plastic materials and ran across an old article about moldmaking. I glanced at the title photo (below) and thought, "That sure looks like Adam Savage."

Well, lo and behold .. the "facing" page, which was underneath this one in the stack, named the author.

I included a bit of the last page of the article below the "facing page," so you could see the author's blurb. Interestingly enough, though this article came out in 2013, it does not mention Mythbusters (2003-2016).

Here's a link to the full article: https://makezine.com/projects/make-08/primer-moldmaking/

Well, lo and behold .. the "facing" page, which was underneath this one in the stack, named the author.

I included a bit of the last page of the article below the "facing page," so you could see the author's blurb. Interestingly enough, though this article came out in 2013, it does not mention Mythbusters (2003-2016).

Here's a link to the full article: https://makezine.com/projects/make-08/primer-moldmaking/

- Joined

- Mar 21, 2018

- Messages

- 1,597

Your stops should be near the periphery of the disk as opposed to where you are right now. Any errors where you are measuring now will be multiplied at the edges. Also, a four legged chair almost never sits on a flat floor as opposed to a three legged chair, which always does. If you're trying for 0.001" or better, I believe that you're going to need to modify your setup some.

Also, there was a good point made about the SHCS not necessarily being flat on the top. A better approach would be to turn off the socket part of the screw and put a slight radius on what remains. You only want one point on each screw to make contact with your flat.

Also, there was a good point made about the SHCS not necessarily being flat on the top. A better approach would be to turn off the socket part of the screw and put a slight radius on what remains. You only want one point on each screw to make contact with your flat.

- Joined

- Sep 1, 2020

- Messages

- 794

Thanks for the input, all you say has been proven to be true. I was able to get under a thou. everywhere But with voodoo magic. I made the stops for sizes i normally work on and almost drilled a more outboard set of holes for the SHCS for this. No doubt, I'd have been better off with the three jaw with a stop. My friend tried to explain a stop for the three jaw but I just wasn't following. I also was concerned about a 10" disk in a 10" chuck but with soft jaws or just a good stop, it would have been fine. Since I don't have variable spindle speed I know I would get more cutting pressure in the center of the disk. I quit cutting the last 2.25" of center and removed it before flipping. As far as the SHCS go, the low head ones have what seem to be machined heads as opposed to normal stamped ones. I still locked them ans took a skim cut. It wasn't good enough. Aluminum wire, fine adjustment, an indicator and voodoo tapping with a magic hammer followed by turning the disk while holding my breath got is done. The rim is thicker than the center but just a little about a thou. or so at most.Your stops should be near the periphery of the disk as opposed to where you are right now. Any errors where you are measuring now will be multiplied at the edges. Also, a four legged chair almost never sits on a flat floor as opposed to a three legged chair, which always does. If you're trying for 0.001" or better, I believe that you're going to need to modify your setup some.

Also, there was a good point made about the SHCS not necessarily being flat on the top. A better approach would be to turn off the socket part of the screw and put a slight radius on what remains. You only want one point on each screw to make contact with your flat.