-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

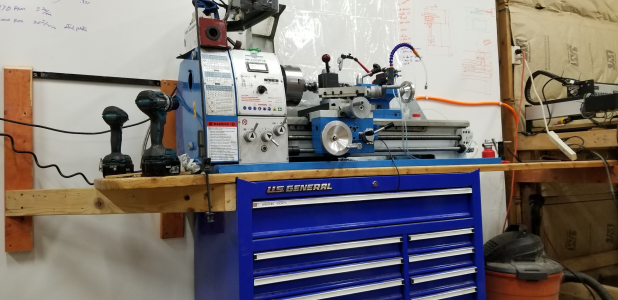

Vibration with Mill and Lathe on Toolbox

- Thread starter sundewzer

- Start date

That is the plan for the future. This was just to see if it would get better. Either that or I will just go completely overkill and surround it in concrete.How about building a steel tube frame to support both the toolbox and lathe, one slightly longer than the lathe?

- Joined

- Jul 10, 2013

- Messages

- 1,190

Your video on the standing wave is better than my explanation. This reminds me of the time I had to find a problem with an organ in a church. One base note coupled with the room put out a perfect standing wave. You could walk around the room and in certain places could hear no sound (the node). The solution was to install a Leslie speaker. A Leslie speaker has a rotating baffle. The wave is always there, but now it is moving. Problem solved.

Now in your case, when you bolted the board to the wall, you changed the resonate frequency. I suspect that something is slightly out of balance in your lathe. Try doing a process of elimination. Such as take the belt off the motor. Does it still vibrate (might be at a different frequency) when you turn on the motor ? You could have a pulley that is out of balance. If it does not vibrate, then put the belt back on. Disconnect the gear to the spindle. Maybe the pulley to the spindle is out of balance. I'm kind of guessing here, since I'm not familiar with your lathe. However, I think that you will get the idea.

Now in your case, when you bolted the board to the wall, you changed the resonate frequency. I suspect that something is slightly out of balance in your lathe. Try doing a process of elimination. Such as take the belt off the motor. Does it still vibrate (might be at a different frequency) when you turn on the motor ? You could have a pulley that is out of balance. If it does not vibrate, then put the belt back on. Disconnect the gear to the spindle. Maybe the pulley to the spindle is out of balance. I'm kind of guessing here, since I'm not familiar with your lathe. However, I think that you will get the idea.

- Joined

- Apr 23, 2018

- Messages

- 6,544

There are two factors that decrease noise in a system like this: mass and rigidity. You are working on rigidity with the new lumber, but have you considered adding mass to the system? Mass can change the resonant frequency of the system and damps the amplitude. If you put a 25-lb sand bag on each corner of your table, I bet it will feel a whole lot different. You could move mass up top, like if you store chucks in the bottom drawer, they may quiet the system if you moved them to the top (so it takes more energy to move the table top around due to mass). If the panels of your tool box are vibrating, cover them with tar flashing or cool stickers to add mass. Fill voids in the underside of your machine casting with epoxy granite to steady the machine itself. Put the machine on 1" steel plates under the bed feet. Lots of ways to do it, I'm just surprised that mass loading wasn't mentioned sooner with some of the sharp folks we've got here.

I put 100 to 150 lbs of plates on next to the spindle and got it smooth up to 1300.There are two factors that decrease noise in a system like this: mass and rigidity. You are working on rigidity with the new lumber, but have you considered adding mass to the system? Mass can change the resonant frequency of the system and damps the amplitude. If you put a 25-lb sand bag on each corner of your table, I bet it will feel a whole lot different. You could move mass up top, like if you store chucks in the bottom drawer, they may quiet the system if you moved them to the top (so it takes more energy to move the table top around due to mass). If the panels of your tool box are vibrating, cover them with tar flashing or cool stickers to add mass. Fill voids in the underside of your machine casting with epoxy granite to steady the machine itself. Put the machine on 1" steel plates under the bed feet. Lots of ways to do it, I'm just surprised that mass loading wasn't mentioned sooner with some of the sharp folks we've got here.

Your video on the standing wave is better than my explanation. This reminds me of the time I had to find a problem with an organ in a church. One base note coupled with the room put out a perfect standing wave. You could walk around the room and in certain places could hear no sound (the node). The solution was to install a Leslie speaker. A Leslie speaker has a rotating baffle. The wave is always there, but now it is moving. Problem solved.

Now in your case, when you bolted the board to the wall, you changed the resonate frequency. I suspect that something is slightly out of balance in your lathe. Try doing a process of elimination. Such as take the belt off the motor. Does it still vibrate (might be at a different frequency) when you turn on the motor ? You could have a pulley that is out of balance. If it does not vibrate, then put the belt back on. Disconnect the gear to the spindle. Maybe the pulley to the spindle is out of balance. I'm kind of guessing here, since I'm not familiar with your lathe. However, I think that you will get the idea.

I went through everything again and now it appears to be the chuck! Before I added the wall brackets it still vibrated pretty bad with the chuck off but now it is smoooooth. There might be a little more vibration at 1100RPM but I think I only notice it because I am looking for it.

How do you balance a chuck? I guess I will go and put the 4 jaw on and see if it has the same issue.

- Joined

- Jul 10, 2013

- Messages

- 1,190

I'm not sure, but it looks like that we are getting somewhere. Here is an idea. Try putting one of those little super magnets on the light side of the chuck. You will have to experiment where that is. Also, just do a little bit of weight at a time. If the vibration gets less, then we are getting some place. Do you have a face plate? If you do, see if it will vibrate with that. I'm asking because the lathe vibrates with two different chucks. I'm asking, because I don't think it's the chucks. Besides, I'd hate to mess with a chuck unless we are absolutely sure. I don't know if it's a gear or pulley on the left side of the spindle. What ever, I would check that very carefully. It could be out of balance or have a wobble. Come to think about it, do this first. See if there is any wobble on the belt pulleys.The 4 jaw does the same thing but at 1400RPM. Which I guess makes sense because it is heavier? Does that point to the spindle being out of balance?

- Joined

- Mar 22, 2014

- Messages

- 847

I have my lathe and mill mounted on toolboxes too - similar to yours. I found that replacing the casters with hockey pucks made a huge difference. But I see that you have already removed the casters. Is the base of the lathe flat against the floor or does it rock on the floor? If it rocks, some sort of leveling might help.