- Joined

- Nov 14, 2020

- Messages

- 1,739

If it hums but doesn't start then : the high speed winding is energized but it needs the start winding to "tip" it into rotation. You either have a bad capacitor or a bad switch.

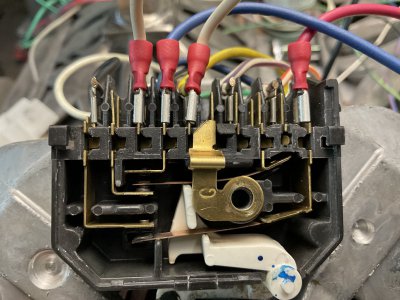

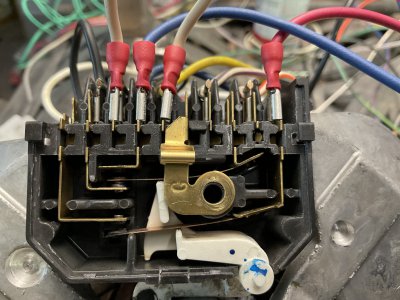

My comment earlier was that the contact for start looked burnt.

Disconnect all power. Short the capacitor by connecting the two terminals for a moment, you might see an arc.this is very important as it discharges the stored energy in the capacitor. I can't stress enough how important this step is.

Then test the switch leads no 1 & no 10 with your proven ohm meter. Proven = connect test leads together and verify the meter reads zero ohms.

A test for the capacitor if you don't have a meter that test capacitance is,

If you take your ohm meter and with the leads to the capacitor Disconnected (you did short it, correct?) Connect one lead to each terminal the ohms reading should increase.

Reverse the leads again the meter reading should slowly build, with a digital meter it might show a negative value but that's not important.

I see the start switches on the internet for about 100.00 average.

My comment earlier was that the contact for start looked burnt.

Disconnect all power. Short the capacitor by connecting the two terminals for a moment, you might see an arc.this is very important as it discharges the stored energy in the capacitor. I can't stress enough how important this step is.

Then test the switch leads no 1 & no 10 with your proven ohm meter. Proven = connect test leads together and verify the meter reads zero ohms.

A test for the capacitor if you don't have a meter that test capacitance is,

If you take your ohm meter and with the leads to the capacitor Disconnected (you did short it, correct?) Connect one lead to each terminal the ohms reading should increase.

Reverse the leads again the meter reading should slowly build, with a digital meter it might show a negative value but that's not important.

I see the start switches on the internet for about 100.00 average.