- Joined

- Mar 3, 2017

- Messages

- 744

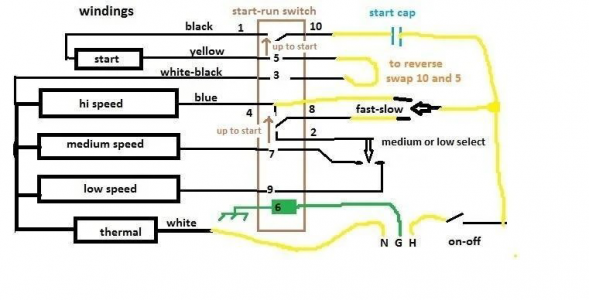

It may be that the start winding is NOT a centrifugal switch inside the motor mechanism, but rather is another

element controlled by the appliance smarts. The way to implement that, is with a momentary contact

switch (press-to-start?) in addition to the main power switch, to start the motor.

element controlled by the appliance smarts. The way to implement that, is with a momentary contact

switch (press-to-start?) in addition to the main power switch, to start the motor.