- Joined

- Aug 6, 2015

- Messages

- 3,886

When I got my first milling machine 5 years ago, a Grizzly G0704, it was out the need to mill a brake caliper so I could mount a different wheel on my motorcycle... Well, not really out of the need to modify the caliper... I could have taken the caliper to a machine shop and had it modified for a heck of a lot less than what I spent on the milling machine.

The truth is that I always wanted a milling machine and a lathe... some background history, my father grew up in Lorain, Ohio. After getting out of the Marines he went to work in a machine shop... after a few years he moved to Puerto Rico and then went on to start his own business making ornamental blocks. He made all his molds. These are concrete ornamental blocks that were made using molds but everything to make the block was done by hand. He used his skills as a machinist to make the molds, and any machine he needed for that process. Later on he added a hardware store and construction materials to the business... He met my mom when I was 1-2 years old... married and they had 7 children... so I am the eldest of 8.

Even if I was not his biological son, he raised me just like it and I was actually the one that was closest to him..funny how that is. In trips we made to Ohio to visit family we would stop by the machine shop where he used to work, just to shoot the breeze with the owner... Seeing all those machines always picked my interest, but at the time, not enough to learn anything... My dad never stopped creating/inventing stuff... That was part of the reason I became an engineer... that and the fact that I can't see blood, or I would have tried going to medical school...

Fast forward... both my parents are gone... I get to meet my biological father, guess what? He was a machinist... retired from it.

I always liked taking things apart and, sometimes, even putting them back together...

Working in my cars, and motorcycles... and having friends asking favors to help them build something... got me hooked on this hobby. I thought that the G0704 would be enough for what I was planning to do when I retire in 4-5 years... Boy was I wrong...

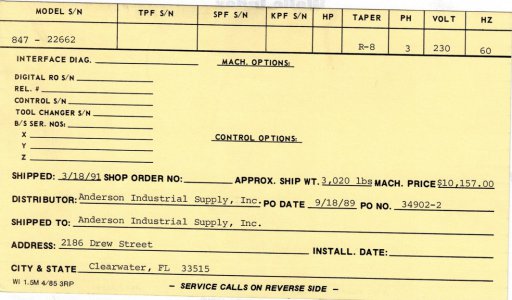

I am now the owner of a 1989 Wells-Index 847 standard head milling machine with a 10"x48" table!

And I should be picking up a 14"x40" used Grizzly lathe later this week. Thank you to all that contributed to this thread - Feedback on selecting a milling machine - where I needed help deciding on which machine to go for...

When my friends ask me if I have gone nuts and why do I need such huge machines, I just text them back with this:

I have no plan to make this produce any kind of revenue... There is no reason/justification for this madness, this is just my way to relax and plan how I will spend my time during retirement... We recently go a smaller house that we plan to move there in 4-5 years... Three-car garage and the single bay will have these machines... Hopefully I can build a small workshop/detached-garage in the back and move the car projects and motorcycles there... so my wife can finally, for the first time since we got married, have a place to park her car inside the garage...

To tell you that I feel like a child in Christmas, is an understatement... very excited and daydreaming of learning and using these machines.

Sorry for the rambling... had to share... pretty excited as you can all tell by now...

Found the milling machine searching Facebook Marketplace and Craigslist. Bought it from a machine shop that had just moved to a larger facility and was also in the process of switching out some of the manual machines for CNC. They needed the space and $$ for that.

Photos when I went to look at it:

Table has seen its share of mishaps... but nothing that I can see interfering with normal use...

Video of one of the guys at shop, showing me the machine running.

Will continue in a little bit... will be right back.

The truth is that I always wanted a milling machine and a lathe... some background history, my father grew up in Lorain, Ohio. After getting out of the Marines he went to work in a machine shop... after a few years he moved to Puerto Rico and then went on to start his own business making ornamental blocks. He made all his molds. These are concrete ornamental blocks that were made using molds but everything to make the block was done by hand. He used his skills as a machinist to make the molds, and any machine he needed for that process. Later on he added a hardware store and construction materials to the business... He met my mom when I was 1-2 years old... married and they had 7 children... so I am the eldest of 8.

Even if I was not his biological son, he raised me just like it and I was actually the one that was closest to him..funny how that is. In trips we made to Ohio to visit family we would stop by the machine shop where he used to work, just to shoot the breeze with the owner... Seeing all those machines always picked my interest, but at the time, not enough to learn anything... My dad never stopped creating/inventing stuff... That was part of the reason I became an engineer... that and the fact that I can't see blood, or I would have tried going to medical school...

Fast forward... both my parents are gone... I get to meet my biological father, guess what? He was a machinist... retired from it.

I always liked taking things apart and, sometimes, even putting them back together...

Working in my cars, and motorcycles... and having friends asking favors to help them build something... got me hooked on this hobby. I thought that the G0704 would be enough for what I was planning to do when I retire in 4-5 years... Boy was I wrong...

I am now the owner of a 1989 Wells-Index 847 standard head milling machine with a 10"x48" table!

And I should be picking up a 14"x40" used Grizzly lathe later this week. Thank you to all that contributed to this thread - Feedback on selecting a milling machine - where I needed help deciding on which machine to go for...

When my friends ask me if I have gone nuts and why do I need such huge machines, I just text them back with this:

I have no plan to make this produce any kind of revenue... There is no reason/justification for this madness, this is just my way to relax and plan how I will spend my time during retirement... We recently go a smaller house that we plan to move there in 4-5 years... Three-car garage and the single bay will have these machines... Hopefully I can build a small workshop/detached-garage in the back and move the car projects and motorcycles there... so my wife can finally, for the first time since we got married, have a place to park her car inside the garage...

To tell you that I feel like a child in Christmas, is an understatement... very excited and daydreaming of learning and using these machines.

Sorry for the rambling... had to share... pretty excited as you can all tell by now...

Found the milling machine searching Facebook Marketplace and Craigslist. Bought it from a machine shop that had just moved to a larger facility and was also in the process of switching out some of the manual machines for CNC. They needed the space and $$ for that.

Photos when I went to look at it:

Table has seen its share of mishaps... but nothing that I can see interfering with normal use...

Video of one of the guys at shop, showing me the machine running.

Will continue in a little bit... will be right back.

Last edited:

P.S. I want one too

P.S. I want one too