- Joined

- Aug 6, 2015

- Messages

- 3,892

You know... took me awhile to understand your reply. I first acknowledge with aYou should never burn your fingertips again. Mike

, but after watching a Cheech & Chong movie, it became all clear... Funny man.

, but after watching a Cheech & Chong movie, it became all clear... Funny man.

You know... took me awhile to understand your reply. I first acknowledge with aYou should never burn your fingertips again. Mike

, but after watching a Cheech & Chong movie, it became all clear... Funny man.

, but after watching a Cheech & Chong movie, it became all clear... Funny man.

I have used a standard die holder but used the tail stock quill to push on the back of the die to get it aligned. Works pretty well, but I can see the advantages of this tool too.Tailstock die holder.

Follow up to my purchase.

Yesterday I made 3 odd ball studs for a setup on a wood shaper. First time using the very cheap, very nicely made in India, tailstock die holder. M12-1.75 , 1 1/2" die, slick and easy. 1/2" steel, 7.75" long, turned to 12mm each end, chamfer, thread @ 40rpm, hex block on mill cut 7/16" wrench flats 2" from one end. I've used various methods in the past to get started straight. This is a winner.

I purchased a tailstock die holder from Neils Niche many years ago. Its been great. Real time saver. Now I can handle dies up to 1.5", taps bigger than anything I will ever need. I made one for a 2" die out of a massive piece of 12L14 that runs on a piece of half inch TGP tool steel. I just insert it in a drill chuck.Tailstock die holder.

Follow up to my purchase.

Yesterday I made 3 odd ball studs for a setup on a wood shaper. First time using the very cheap, very nicely made in India, tailstock die holder. M12-1.75 , 1 1/2" die, slick and easy. 1/2" steel, 7.75" long, turned to 12mm each end, chamfer, thread @ 40rpm, hex block on mill cut 7/16" wrench flats 2" from one end. I've used various methods in the past to get started straight. This is a winner.

Been there, done that! LOLRemind me again... what is the first thing to go??? I can't remember...

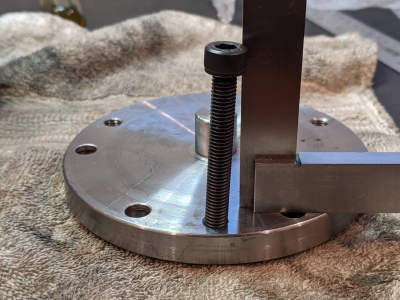

I went to put away what arrived... guess what I found?

View attachment 374283

Good grief...