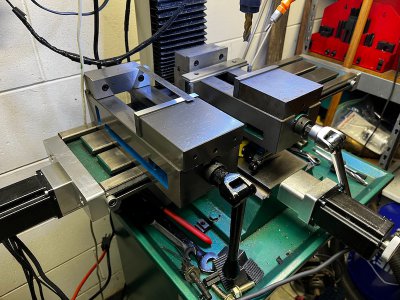

Received these today. Must say, pleasantly surprised. These are heavy... bearing slides... the gray epoxy finish looks to be thick. That is a relief... I thought they would be total flimsy carp...

Photos:

Well packaged...

View attachment 396705View attachment 396706

View attachment 396707

One box (the one above) has all smaller slides...

The other two are the same. With two rows of wider and deeper sections...

View attachment 396708

The finish makes it so that you need some thin double face tape if you are stacking them. They slide easily when stacked... Not sure how I will set them up... maybe side by side on a shelf. Not sure.

View attachment 396709

Bearings... I was not expecting to see these... thought it would be metal to metal slides...

View attachment 396710

So yeah, happy with the purchase/price. Now to get all the drill bits from the cardboard box and into their proper place.