- Joined

- Nov 17, 2020

- Messages

- 1,723

gotta log in to see the price

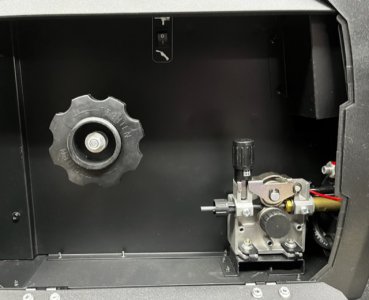

Got this in on Monday and a couple of things I'm not happy about. First of all the gas line uses what seems to be a propitiatory fitting. I've got two other welders with regulators and I can't use either of them. So had to order another regulator from yeswelder to make sure it actually will work. But this is just a one time irritation. Hopefully this next Tuesday the regulator will be here and I can actually weld with it.

Issue is how close to the case the assembly is...Alloy, maybe I dont understand your problem. I don't own a yeswelder, but on my Miller, I run the feed rollers to pull the wire in. Start with about 6" of straight weld wire of the proper dimension of course. Turn the machine on and hit the trigger. I would think it would draw the wire in for you. Am I off base here?