- Joined

- Oct 4, 2016

- Messages

- 7,015

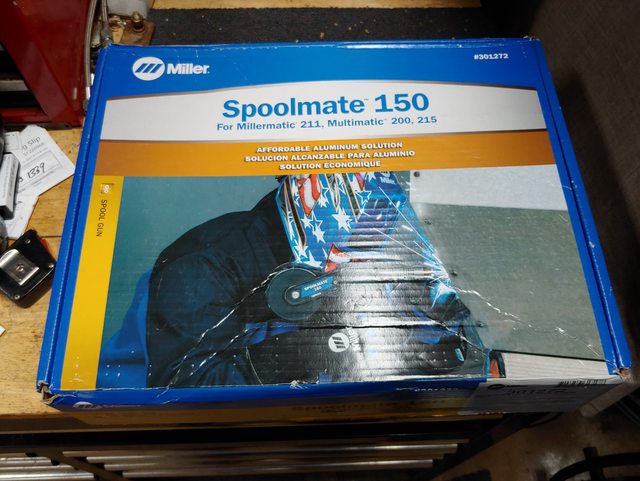

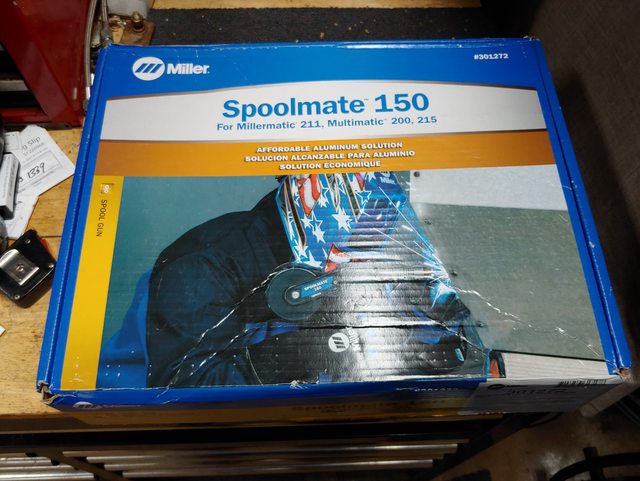

I got so lucky today, a little bit of a long story. My son's boat has cracked welds on his aluminum T top for his boat, the fabricator here has been too busy for over 3 months. In May the miller dealer here had a welding show, and I went to the store today to buy a spool gun so I can take out, and replace the tubing. The counter person(long time employee) said I have to sell you the demo model from the show, I said sure. I bought extra spools, wire brushes, and tips to practice with when he went to make the invoice, and get prices, he said oh, they expensed the gun out, it's free, I just had to pay for the miscellaneous other items.