-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you make with your lathe and mill that's not tooling, a jig or fixture, but something that is useful to the average person?

- Thread starter ARC-170

- Start date

- Joined

- Mar 15, 2019

- Messages

- 708

Since no one else has said it yet.

Maybe you should post a for sale or trade ad, there is always someone out there wanting to trade in what they have for a newer model or one with more capabilities. Or maybe they don't have one at all. Sometimes it is purely cosmetic, they already have one but they want something that looks better than what they already have. Lots of guys seem to want an Asian model though eastern European has been popular here of late.

Word the ad like this. Mill and lathe, wife said she doesn't want to see them anymore. So she has to go.

Of course, if you have had her around for a while, it might just be cheaper to keep her around in the long run.

Maybe you should post a for sale or trade ad, there is always someone out there wanting to trade in what they have for a newer model or one with more capabilities. Or maybe they don't have one at all. Sometimes it is purely cosmetic, they already have one but they want something that looks better than what they already have. Lots of guys seem to want an Asian model though eastern European has been popular here of late.

Word the ad like this. Mill and lathe, wife said she doesn't want to see them anymore. So she has to go.

Of course, if you have had her around for a while, it might just be cheaper to keep her around in the long run.

- Joined

- Feb 1, 2015

- Messages

- 9,647

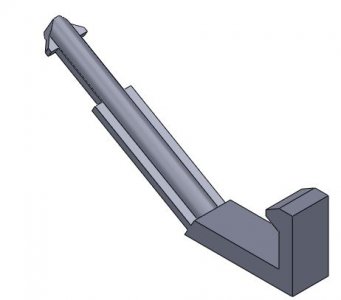

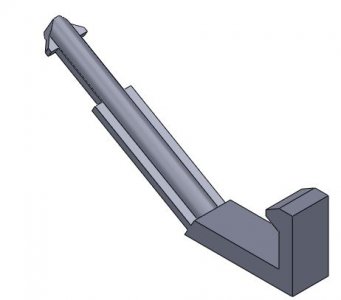

The very first thing that I made on my brand new Tormach CNC was a latch for our Cuisinart tea kettle. The original latch was plastic and broke making the tea kettle useless. Not good when you're married to a Brit.

I reverse engineered the old latch, modeled it in SolidWorks, and cut a new latch from aluminum. It is still functional some eight years later.

I reverse engineered the old latch, modeled it in SolidWorks, and cut a new latch from aluminum. It is still functional some eight years later.

- Joined

- Feb 1, 2015

- Messages

- 9,647

The most recent build was an arbor for an office tape dispenser. The original got lost somehow and the wife asked me if I would repair it (actually, she took mine, leaving me arborless). A walk down to the shop and selecting a piece of HDPE and turning it to a nice snug fit and then boring for an aluminum shaft and turning it to diameter and a new arbor was born. A few minutes work and some scrap materials.

I have tools to fix stuff and make parts for friends. They have expensive street rods, my hobby is relatively cheap. Try working on a 50 year old tractor without a way to make the special tool you couldn't find on a bet. Or you need a fitting, now, and it's a half hour to town or it's Sunday - sometimes expediency trumps cost. New bushing in the end of the skid steer cylinder for friend - have press, make arbor, drink beer, tell lies, everything is good. Tools allow independence. Machine tools is an extrapolation of wrenches and such. Those with minimal inclination end up taking their car to someone to get the oil changed and spend lots of time waiting for repair guys to arrive in a 4 hour window ( if it suits them). I've said it before, not sure how anyone can survive without a least a lathe. Although most do, quality of life notwithstanding, they just don't know what they are missing. If we could start the "everyone needs a lathe" movement, the additional volume would drop prices, quality would go up, things could get so excellent - that's just crazy talk!

- Joined

- Jan 5, 2014

- Messages

- 952

I replaced the steel acme screw and plastic nut on my gate opener with a stainless steel screw and bronze nut. Took almost no time and saved hundreds vs. replacing the whole works. Now I don't need to worry about it rusting out again either. Another 50 jobs like that and the lathe pays for itself!

- Joined

- Feb 1, 2015

- Messages

- 9,647

If I look back on all the4 projects that have come off my machines in the past fifty years, I would bet the the category with the largest share would be items for repair, remodeling, or improvement on this 125 year old farmstead. From items as simple as threading a rod to building a custom firewood saw or a custom wood burning central heating system and everything in between.

For me it is the satisfaction of rescuing a still useful object from landfill or improving on some generally poor engineering and/or workmanship of a commercial product that makes my hobby. When you are twenty five miles away from the nearest shop or when you are dealing with parts which went obsolete decades ago, it becomes something of a necessity as well.

Much of my satisdaction in this hobby comes from knowing that I have the ability to make things right or perhaps even better than they were before. Certainly, it carries over to the tricking out of my tools as well, as is demonstrated in many of my posts on this forum. But in the end, if the tools are solely used to make more tools, what is the point? In the end, you will have a bunch of tools that will most likrly be given or sold to someone with less appreciation than all of your effort deserves.

For me it is the satisfaction of rescuing a still useful object from landfill or improving on some generally poor engineering and/or workmanship of a commercial product that makes my hobby. When you are twenty five miles away from the nearest shop or when you are dealing with parts which went obsolete decades ago, it becomes something of a necessity as well.

Much of my satisdaction in this hobby comes from knowing that I have the ability to make things right or perhaps even better than they were before. Certainly, it carries over to the tricking out of my tools as well, as is demonstrated in many of my posts on this forum. But in the end, if the tools are solely used to make more tools, what is the point? In the end, you will have a bunch of tools that will most likrly be given or sold to someone with less appreciation than all of your effort deserves.