- Joined

- May 16, 2016

- Messages

- 1,698

Nice, almost machine shop porn.

That is a cool background on it once I get I shop I would love to make one of those or pick one up pretty handy tool to haveBack when I was a youngster, trying to absorb everything I could about metalworking, I was a student in the Machine Technology program at San Jose City College. I graduated in 1984 and made this tool my last semester there, whatever the final class was... I can't remember. No CNC in the program yet, all manual machining. Anyway, I had completed my required projects and had lots of time to make whatever I wanted. There was a British guy where I worked, a tool and die maker who made one of these in the 50's while an apprentice in England. I always thought it was cool, and very useful. So I made one. They are available in various tool catalogs, but they are tiny. I borrowed the brit tool and diemaker's one and made a crude drawing. It's 4.25 dia x 2" high. His was made from a solid chunk of O-1... I didn't have any of that so I used mild steel and had it case hardened. Still one of my most used tools.

View attachment 348900View attachment 348901

You where about to get a big you suck but I can’t add one or use anything on the top barMine would be the Starrett C359. Got it at a closing auction at a machine shop in Laval Qc, summer of 2016. $75 +tax I got opening bid. Now its worth almost $1k CAD to replace. Spent perhaps too much on tooling during my apprentice years, bargain hunting and such.

Its an amazing tool, only I barley use it. For rough purposes, scribe lines and such, I used the protractor on a combination square. For finer work that had a discerning angle tolerance, I needed to use a sine bar or angle wedges on the granite plate. My current work as the Mitutoyo version. The "Vernier Bevel Protractor, 0-320°" is better I find for tool bit grinding, as the inner wedge is held to the tool against the light , also I don't mind getting grinding dust on it. So the starrett remains near mint.

View attachment 347811

You where about to get a big you suck but I can’t add one or use anything on the top bar

I like the file handle on the hammer nice touch and that carbide scraper looks like a wood planer blade but probably notThree tools today...

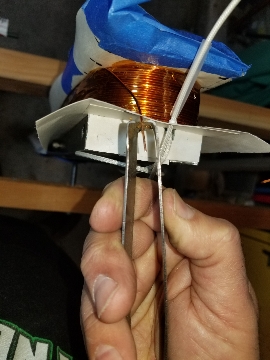

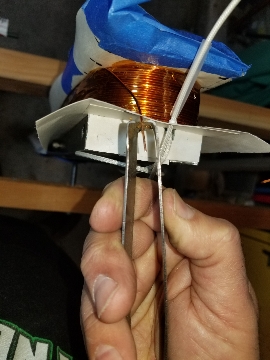

My grandfather made this magnet wire stripper and brass hammer

The hammer gets a lot of use, but the wire stripper only comes out when I'm working with magnet wire. Like today, winding my Magnabend!

I dont know -what- they are actually for, but I have a couple and I use them all the time! The are carbide, straight, flat, sharp, and have a polished and rounded back. I'm always scraping things with them!

Sent from my SM-G892A using Tapatalk

Back when I was a youngster, trying to absorb everything I could about metalworking, I was a student in the Machine Technology program at San Jose City College. I graduated in 1984 and made this tool my last semester there, whatever the final class was... I can't remember. No CNC in the program yet, all manual machining. Anyway, I had completed my required projects and had lots of time to make whatever I wanted. There was a British guy where I worked, a tool and die maker who made one of these in the 50's while an apprentice in England. I always thought it was cool, and very useful. So I made one. They are available in various tool catalogs, but they are tiny. I borrowed the brit tool and diemaker's one and made a crude drawing. It's 4.25 dia x 2" high. His was made from a solid chunk of O-1... I didn't have any of that so I used mild steel and had it case hardened. Still one of my most used tools.

View attachment 348900View attachment 348901

Meat tenderizer. LolOk. I give up. What is it?