A "wiggle bar" would make good use out of one of those printer rods. I don't know what kind of steel they are, but all the ones I've used have turned very nicely.

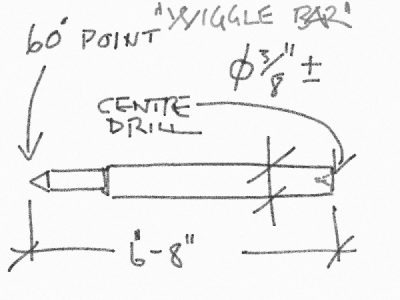

So what's a wiggle bar? Simply a rod with a point turned accurately on one end and a centre drill hole in the other. You can use it for centring work in a chuck where the outside of the work might not be a useful reference. If you have a centre punch mark the pointy end of the bar rests in the mark, the other end is supported on a tailstock centre, and an indicator placed against the bar near the chuck. When the bar registers zero runout (or as close as you can get it) on your indicator as you rotate the chuck by hand, the centre punch mark on the stock is centred in the chuck. This is also useful for when you want to purposefully offset work in the chuck, such as a crankshaft lobe or something.

I don't know if it's really called a wiggle bar or something else, I just heard it called that and continue to do so myself. Here's a sketch, dimensions are not critical:

View attachment 273510

-frank