- Joined

- Jul 8, 2018

- Messages

- 880

Well, there's a difference between an insert of the type used in your holder not being available at all, and it being a bad idea to use that insert in your specific holder or on your specific lathe.

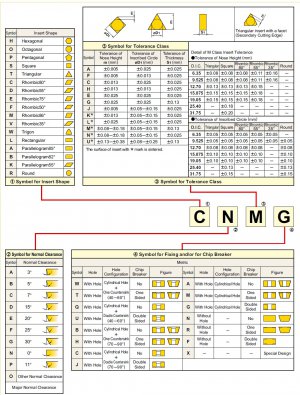

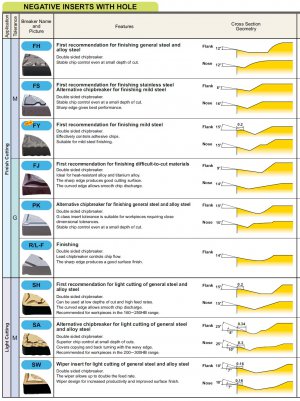

The insert type for the trigon holder you posted seems to be pretty widely available. I don't know enough about the holder to say whether there will be problems using a positive rake insert in it. Inserts are cheap, though, and can be bought singly (e.g. from shars, travers), so you can just get one and give it a go, see how it cuts. Maybe it cuts bad, maybe you break the insert, maybe it works out great.

Don't forget, you can also use a diamond hone or a diamond burr (e.g. for a dremel) to modify the insert - sharpen the edge, increase the nose radius, add a chip breaker, maybe even change the rake (might be too much, they are just sintered powder after all). Same goes for those crappy brazed carbide tools.

The insert type for the trigon holder you posted seems to be pretty widely available. I don't know enough about the holder to say whether there will be problems using a positive rake insert in it. Inserts are cheap, though, and can be bought singly (e.g. from shars, travers), so you can just get one and give it a go, see how it cuts. Maybe it cuts bad, maybe you break the insert, maybe it works out great.

Don't forget, you can also use a diamond hone or a diamond burr (e.g. for a dremel) to modify the insert - sharpen the edge, increase the nose radius, add a chip breaker, maybe even change the rake (might be too much, they are just sintered powder after all). Same goes for those crappy brazed carbide tools.