-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yet Another VFD problem

- Thread starter randyjaco

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,313

What was the magic recipe Randy?

- Joined

- Oct 5, 2010

- Messages

- 1,043

God, I hate dealing with electronics

My panic switch finally arrived yesterday. https://www.ebay.com/itm/333167831488

But they failed to provide any wiring instructions. The vendor hasn't responded yet and I haven't got a clue on how to wire it to my VFD. I presume it is upstream of the VFD, but that is it. I will be powering it with single phase 220vac. Once again, any help would be appreciated.

My panic switch finally arrived yesterday. https://www.ebay.com/itm/333167831488

But they failed to provide any wiring instructions. The vendor hasn't responded yet and I haven't got a clue on how to wire it to my VFD. I presume it is upstream of the VFD, but that is it. I will be powering it with single phase 220vac. Once again, any help would be appreciated.

Attachments

- Joined

- Jun 12, 2014

- Messages

- 4,812

You normally use the ON/OFF button for VFD input power, the E-Stop in this application typically does not interrupt power to the VFD, but is used to interrupt any connection from the common (GND) to any of the forward/reverse/run inputs. So a NC connection, which goes open when you push the E-Stop. You also need to be aware that in this VFD that it only has 2-wire control, so if you hit the E-Stop while a run command is engaged, and then release the E-Stop, the motor will restart and is very dangerous. If you want to kill power to the VFD then wire both hots to the E-Stop (NC switch blocks) and then to VFD input power, when releasing the E-Stop, P07 = 1 should prevent a run command from restarting the VFD on power up. With 3-Wire control which uses momentary buttons, any interruption of the inputs common would result in the VFD not restarting, one can also use a power latching relay.

In some cases if an input can be programmed for an emergency stop which would use a NO -> NC to activate the input when the E-Stop is pressed, but not this VFD. By keeping power to the VFD electronic braking is maintained, if power is disconnected it may stop slower or go into a free run mode. In industrial application, there is a usually a monitored loop to the E-Stop, dual redundancy, and the output drive section of the VFD is disabled (STO, Safe Torque Off).

In some cases if an input can be programmed for an emergency stop which would use a NO -> NC to activate the input when the E-Stop is pressed, but not this VFD. By keeping power to the VFD electronic braking is maintained, if power is disconnected it may stop slower or go into a free run mode. In industrial application, there is a usually a monitored loop to the E-Stop, dual redundancy, and the output drive section of the VFD is disabled (STO, Safe Torque Off).

- Joined

- Oct 29, 2012

- Messages

- 1,328

NOTE that the "proper" means of e-stopping a VFD is not by removing input power like you will be doing with this magnetic switch. Because the VFD can store energy and continue running for a (brief) time after power is removed. The "proper" way to do it is by removing the "base block" or "gate block" or "STO" input from the VFD. But your VFD does not have this input. So this switch is the best you can do, and should be "good enough" even if it wouldn't fly in a "by the book" production setting.

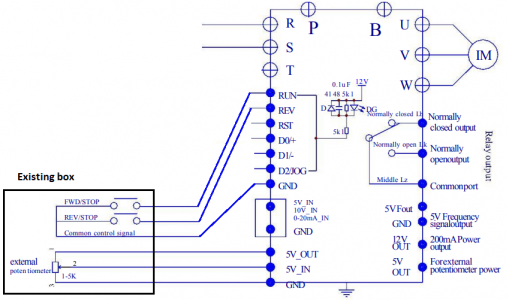

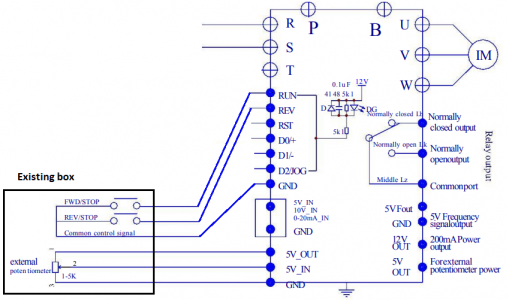

If I'm correct about your existing setup, it should be something like this:

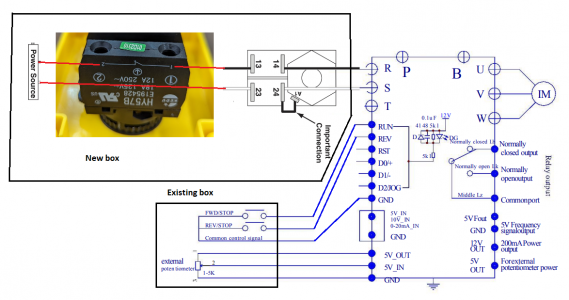

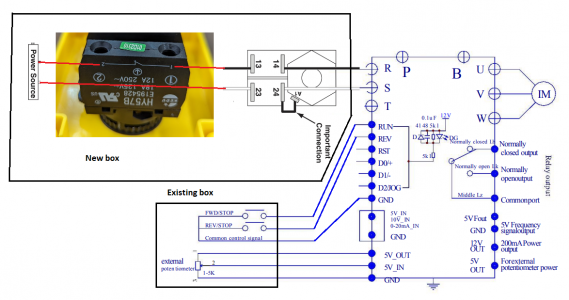

And I would suggest wiring the new box in something like this:

If I'm correct about your existing setup, it should be something like this:

And I would suggest wiring the new box in something like this:

- Joined

- Oct 29, 2012

- Messages

- 1,328

We posted with a minute of each other saying basically the same thing LOL.You normally use the ON/OFF button for VFD input power, the E-Stop in this application typically does not interrupt power to the VFD, but is used to interrupt any connection from the common (GND) to any of the forward/reverse/run inputs. So a NC connection, which goes open when you push the E-Stop. You also need to be aware that in this VFD that it only has 2-wire control, so if you hit the E-Stop while a run command is engaged, and then release the E-Stop, the motor will restart and is very dangerous. If you want to kill power to the VFD then wire both hots to the E-Stop (NC switch blocks) and then to VFD input power, when releasing the E-Stop, P07 = 1 should prevent a run command from restarting the VFD on power up. With 3-Wire control which uses momentary buttons, any interruption of the inputs common would result in the VFD not restarting, one can also use a power latching relay.

In some cases if an input can be programmed for an emergency stop which would use a NO -> NC to activate the input when the E-Stop is pressed, but not this VFD. By keeping power to the VFD electronic braking is maintained, if power is disconnected it may stop slower or go into a free run mode. In industrial application, there is a usually a monitored loop to the E-Stop, dual redundancy, and the output drive section of the VFD is disabled (STO, Safe Torque Off).

Just so I'm clear, I'm not disagreeing with the method you suggested (removing run signal); that is also a viable option. Interrupting VFD input power isn't proper and neither is removing the run signal. I'm just discussing the lesser of to weevils. The down-side of interrupting input power is that the drive can still run for a short while (maybe a couple of seconds) before faulting out. The downside of removing the run signal is that the drive will (guaranteed) continue to run for a few seconds - however many seconds you've set for the decel parameter. If that's up at 10 seconds or so, that's an awfully long time to sit there waiting patiently for your body to stop being mutilated if you happen to be caught in the machine at the time you hit e-stop. But, if the machine has a lot of inertia then free-wheeling to a stop (after input power removed) might take even longer! Damned if you do, damned if you don't. The call IMO should be made by TS after studying the behavior after removing input power vs pressing stop, and making an informed decision.

- Joined

- Oct 5, 2010

- Messages

- 1,043

Yes, I have that, but it is just a remote for the VFD. The on/off switch turns the motor on and off, but does not remove power to the VFD. (I now plan not to use it) I need a switch to power up and shut down the VFD, so I opted for the panic switch to provide some safety since the VFD is attached to the planer itself.Forgive me if I'm getting you mixed up with someone else but if I remember correctly you already have a small remote box with FWD/Stop/REV switch and speed pot, correct?

- Joined

- Oct 5, 2010

- Messages

- 1,043

Wow, this is getting complicated really fast! I do appreciate the input, but please bear with me.

Starting from the beginning, I will try to explain the situation. The device is a 220 vac 3 phase wood planer and my power source is 220vac single phase. The VFD I have seems to be satisfactory for this application. The motor should run only in one direction and at one speed (60Hz). The VFD is mounted to the planer, so I need to have a means to turn on/off power to the VFD and a means to turn the motor on and off when the VFD is powered up. The planer rotor has a lot of mass, so it is somewhat slow to start up and reach full speed and to shut down. These natural acceleration and deceleration are satisfactory as they are now, so I don't need a quick stop, but I don't want to make them take any longer either. I guess the panic switch was the wrong purchase. So what would be the best way to accomplish the following:

1. Power up the VFD

2. Turn on the motor

3. Turn off the motor

4. Power down the VFD

Starting from the beginning, I will try to explain the situation. The device is a 220 vac 3 phase wood planer and my power source is 220vac single phase. The VFD I have seems to be satisfactory for this application. The motor should run only in one direction and at one speed (60Hz). The VFD is mounted to the planer, so I need to have a means to turn on/off power to the VFD and a means to turn the motor on and off when the VFD is powered up. The planer rotor has a lot of mass, so it is somewhat slow to start up and reach full speed and to shut down. These natural acceleration and deceleration are satisfactory as they are now, so I don't need a quick stop, but I don't want to make them take any longer either. I guess the panic switch was the wrong purchase. So what would be the best way to accomplish the following:

1. Power up the VFD

2. Turn on the motor

3. Turn off the motor

4. Power down the VFD