- Joined

- May 12, 2014

- Messages

- 164

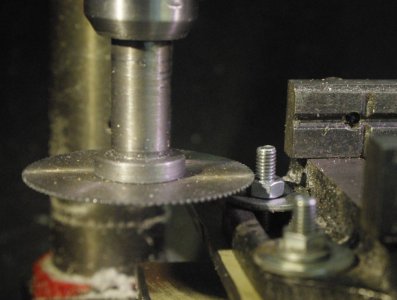

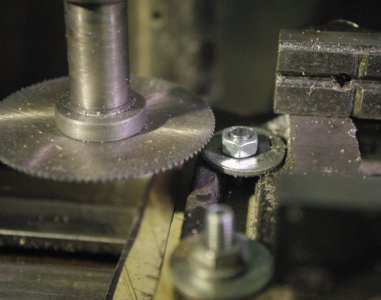

Had some time today to make this arbor:

No keyway just yet I'll try it out first to see if it needs one.

Apparently more forgiving to the saw should it grab (may shatter).

The "saw contact face" on the shaft has been undercut toward outside diameter.

A flat ring area left so when the blade is sandwiched the holding force will be greater.

It's a one inch shaft

I roughed it then left .012 on all diameters then tuned it between centers for trueness.

dd

No keyway just yet I'll try it out first to see if it needs one.

Apparently more forgiving to the saw should it grab (may shatter).

The "saw contact face" on the shaft has been undercut toward outside diameter.

A flat ring area left so when the blade is sandwiched the holding force will be greater.

It's a one inch shaft

I roughed it then left .012 on all diameters then tuned it between centers for trueness.

dd